-

Stop Taking Heads Cuts

@DonMateo said: I only take about maye 5% in my stripping run for a whiskey. I will take a litre or more, in a 300l stripping run where I will get about 40l of low wines. About the same with a spirit run. As well I always go deep into the tails. My final spirit on the spirit run is about 51 to 52%. There is so much more flavor in spirits that you dont get when you take more narrow cuts. A couple of years ago I had a woman over to my house to taste my whiskeys. She used to be the head of quality control for Seagrams and was a professional taster and had 20 people also tasters working under her. When she tried most of my whiskys as teh time he comment was you always go into the tails. I said yes and she said thats great as there are some fantastic flavors in the tails that almost all distillers dont get into.

My experience with rums (for my personal taste) is that whiskey is far more forgiving than rum in the tails department. It is the heads that contribute to the more familiar aromatic rum qualities that I think of when I think of rum. Banana, pineapple, coco nibs, stone fruit etc.

Stop Taking Heads CutsI only take about maye 5% in my stripping run for a whiskey. I will take a litre or more, in a 300l stripping run where I will get about 40l of low wines. About the same with a spirit run. As well I always go deep into the tails. My final spirit on the spirit run is about 51 to 52%. There is so much more flavor in spirits that you dont get when you take more narrow cuts. A couple of years ago I had a woman over to my house to taste my whiskeys. She used to be the head of quality control for Seagrams and was a professional taster and had 20 people also tasters working under her. When she tried most of my whiskys as teh time he comment was you always go into the tails. I said yes and she said thats great as there are some fantastic flavors in the tails that almost all distillers dont get into.

Stop Taking Heads CutsWell, dipped into the two test barrels this week. These were funkier Jamaican style molasses based rums.

First test barrel - normal batch (1 week Ferm), proportional share of heads added back into the barrel.

Second test barrel - this was a longer fermentation (3 weeks Ferm), 5 barrels worth of rum in this batch, the entire heads cut from this volume of rum was added back to 1 of the 5 barrels. I underfilled to leave room to add back the heads cut. The net was far higher proof than the other barrels. I did this on a whim when I was setting up to barrel. Thought first test batch barrel was interesting, why don't I amp it up far beyond that. Not only not taking a heads cut, but adding back and essentially completely concentrating the heads volume unnaturally by 5x. Now, our heads cuts on this style are never nasty, in fact I love opening the feints tank for a smell.

Both barrels are fantastic, and exhibit characteristics that I've been missing from our rums. Our white is normally a 1.5x distillation style, very flavorful, but very clean on the nose. Dark rum, even with heavy dunder and bacterial fermentation, close, but still far away.

Only about 6 months in a 30g ex-bourbon at this point, so still very young, but f*ck me the 5x concentrated heads is fantastic. Based on what I'm tasting right now, this will undoubtedly be the best barrel of Jamaican style dark rum we've ever made.

Take it however you want.

KojiThis is a great video on making sake.

https://www.youtube.com/watch?v=UA83cK1Xouk

Mad respect for this guy. Every artesenal distiller knows that felling of sweating your ass off and wondering what am I doing only to taste your product and be satisfied you have created something new.

GNS Continuous Still?@grim said: Jesus, 14 years ago…

We were all doing so much experimentation at that stage. most of us didn't have the science of it like you guys, a lot was 'what if'.

Everything from equipment, to methods, to recipes.

@Smaug's thumper pumper was out there too.....

@olddog brought the bubble plate column to the hobby world not long before we all started StillDragon and doing all our product development.

Was a cool time to be part of the hobby.

GNS Continuous Still?Jesus, 14 years ago…

GNS Continuous Still?Not at all wrong.

I tried this once using 100% neutral, on accident. Had the water valve off, so I was pumping only neutral. Flavor profile was very different. I let it run through for a while for the hell of it. Then, not sure why, I decided to just try running water alone, and just running steam through.

The end result was very similar to the normal run. Each individual component was not. The steam distilled botanicals ran white like milk. But as soon as the distillate hit the very-high-proof first runnings, it went clear again.

Toyed around a few times after that, but when I ran a vapor proof that was identical to my batch distilled product proof (before dilution), the end result was identical.

The best I could posit was, the same amount of alcohol vapor and water vapor is passing through the botanicals. The only difference is that they are constant through the run, and not starting high/ending low/vice-versa.

Assuming you are getting full extraction of your botanicals, why would the end result differ? it all comes down to grams/liter of extract and oils per finished bottle. Keep those ratios identical, it won't matter.

You could get very fancy with this setup, and vary the ratio of water/ethanol through the run, in a manner similar to a step mash in brewing. (5 minutes at 190 proof, 5 minutes at 150 proof, 17 minutes at 130 proof, 8 minutes at 110 proof, etc, etc). You could actually get better consistency doing this than you ever could with a batch still.

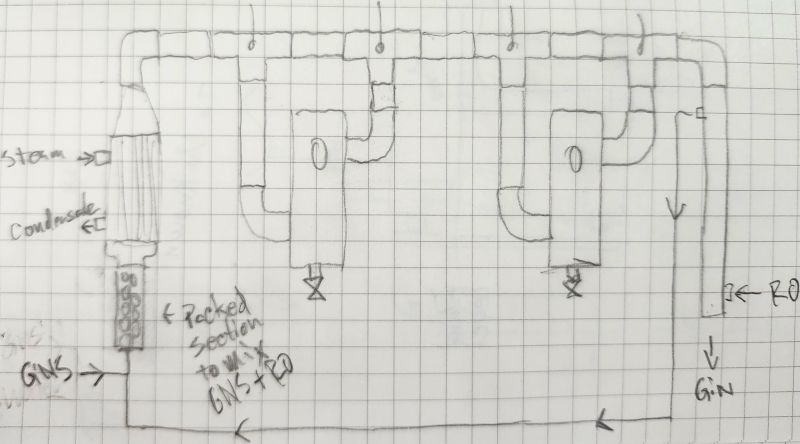

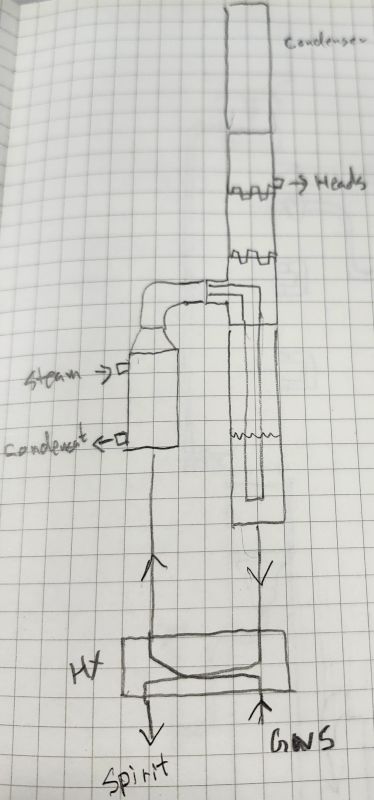

GNS Continuous Still?@grim is this more or less that you had in mind for the continuous gin still?

Rotovap

RotovapThe vacuum rating would also need to apply to the collection vessel, and any associated piping.

Though the piping is probably the least worrisome part of this.

Column diameters do need to be upsized for vacuum use, as the vapor speeds are far higher, and flooding becomes a major issue.

Realistically, you'd probably need a 12" or 18" column on a 380l tank to keep vapor speed in check. Or settle with pot-still only.

Rotovap@DonalF said: Not a rotovap question but a vacuum still question. Does anyone know if the dragonstill pots (specifically the 380 L pot) can work under negative pressures (i.e. under vacuum) and if so, how low can the vacuum go before there's a risk of impolsion? Any idea what thickness of the 304 stainless steel in the wall of the vessel is?

I'm sure @Smaug will answer, but the answer is likely to never run them under any sort of vacuum.

RotovapNot a rotovap question but a vacuum still question. Does anyone know if the dragonstill pots (specifically the 380 L pot) can work under negative pressures (i.e. under vacuum) and if so, how low can the vacuum go before there's a risk of impolsion? Any idea what thickness of the 304 stainless steel in the wall of the vessel is?

GNS Continuous Still?As much heads as a heads cutter cuts if a heads cutter could cut heads.

In high quality neutral, a few parts per million. Looking at the spec sheet from my last order of fcc/usp grade neutral, it is 20 parts per million (sum of all volatile organics, including methanol). So in 50 gallons, that would be about 375-400ml. You can't remove all of it, since not all of it is more volatile, or may form azeotropes, etc.

GNS Continuous Still?@Smaug, I see what you're saying. What I'm thinking is a cross between the GNS continuous and the LM function of the spirit side of your continuous... like a boka but you're taking off the heads at the LM port and your good spirit out of the bottom of the column.

GNS Continuous Still?

GNS Continuous Still?Yeah, I'm trying to work out a few things too including:

Reboiler HX appears to be a 4" x 750mm shell in tube

column

- Diameter? looks to be about 8"

- Length? about 1m?

- Plate type: sieve vs bubblecaps?

- plate count: 4?

- how do the level sensors control the operation of the unit?

condensor

- looks like a 4" x 1m long

- How does it work to take off heads? Are they drawn off via the vent? As there's a flame arrestor I don't think so as it'd also need a condenser for the heads take off

- Is the line from the bottom of the condenser to close to the bottom of the column the condensed hearts?

Pumps

- What would be the specs of the 2 pumps used for feed in and product out?

- Do they run continuous or does the level sensor(s) turn it on/off?

- I think they'd need to be ATEX/IECEX = $$$

- Could double diaphram pneumatic pumps be used instead of electric?

At 2gpm that comes to 462lph! 96% GNS has a boiling point around 78C so the Preheat HX & reboiler don't have as much work to do compared to running a 10% wash which needs to get to about 93C. So trying to work out what I could do with my available power

GNS Continuous Still?That makes sense, thank you

I guess what I dont understand is how they are removing the heads vapor. It appears to be venting out via the fire arrestor, but how does that work? Is the temp in the condenser kept at say 173°f to allow for the etoh the condense but the heads to remain a vapor?

GNS Continuous Still?The operating principal is pretty simple:

- There is a single pass boiler (not reboiler), which vaporizes near 100% of the feed, injecting that vapor into the column, which operates like. thumper. There are no plates in the column.

- Vapor moves up into the condenser, gets condensed, and flows BACK INTO THE "column". You can see the drain located about one quarter/third from the left on the top condenser. It flows to the bottom of the column.

- Column liquid volume is controlled by the level sensor, which operates the discharge valve. There are two pumps, a feed pump, and a discharge pump.

- There is a temperature probe on the vapor vent from the top condenser (port at the top, far end). There is a PID (visible ABB unit) that controls the water flow through that top condenser using the vapor vent temp as process input. The set point controls the amount of input that's removed as vapor.

- The discharge pump drains from the bottom of the column, through the heat exchanger, out.

Everything in the "distillation" stream is product, there are no bottoms (as this is GNS), the only thing removed is a very small amount of "heads" as vapor.

Stripping Run --> Spirit run: How to minimise wastage?@richard said: Seems excessive. Say 125mm diameter x 30 = 3.75m. Normally a minimum of 1.2m packed section is sufficient plus RC etc. on top. I could relate to this if it were plates at pitches of say 100mm and 30 plates were the requirement.

Thanks. Yeah I can't remember what that rule of thumb was.

Stripping Run --> Spirit run: How to minimise wastage?@Smaug said: No sir. The diameter to height ratio for columns with random packing materials.

Seems excessive. Say 125mm diameter x 30 = 3.75m. Normally a minimum of 1.2m packed section is sufficient plus RC etc. on top. I could relate to this if it were plates at pitches of say 100mm and 30 plates were the requirement.

Fats in the Pool?Both methanol and ethanol will react with long chain fatty acids found in meat or vegetables to form the precursors of diesel fuel (FAME/FAEE) - basically just long chain esters. They don't all come across as heads products, the longer chain stuff smears across hearts, tails, and beyond.

I could see locking up some methanol in longer-chain esters, and being able to cut that out as tails.

The protein stuff, that stumps me. I need to study aldehyde chemistry more, aldehydes will react with proteins and amino acids.

Stuff like:

Understanding interactions among aldehyde compounds and porcine myofibrillar proteins by spectroscopy and molecular dynamics simulations

porcine myofibrillar proteins = pork meat

Among flavour compounds, aldehydes have a significant role in flavour development of meat and meat products [9], [10]. Some studies describe the influences of aldehyde characteristics (such as structure and concentration) on their interactions with protein, and some investigations concluded that aldehydes react with amino acid residues of proteins via irreversible covalent binding [20], [21]. Other studies reported that hydrophobic interactions were the predominant force responsible for the interactions among proteins and aldehydes [22]. Based on these studies, both reversible and irreversible binding modes appear to be the major contributors to the interaction among proteins and aldehydes, depending on the specific chemistry and structure of the interacting molecules. Nevertheless, information on the conformational changes that occur in MPs upon aldehyde binding remains limited, and the mechanisms of aldehydes binding to MPs remain unexplored.

Fats in the Pool?Probably aimed mostly @grim.

Is there any evidence to suggest that having fats in the kettle (in this instance a petchuga styled chicken in the vapor path or in the kettle charge) would have a reactive relationship with heads constituents in such a way that it would sequester perceived heads?

Here is the dude's assertion:

About serious cabbage soup.

My colleague carried out a laboratory analysis of a simple distilled sugar mash with a meat composition and vegetable oil IN ONE TIME WITHOUT SELECTING THE FIRST DROPS.

- Aldehydes 68.1 mg/dm3 (norm – 10-350)

- Ketones (acetone) 0.5 mg/dm3 (norm – 0.1-2.34)

- Esters 337.5 mg/dm3 (norm - 10/50 -1500)

- Methanol 0.0005% vol. (norm – 0.05)

- Higher alcohols (fusel oils - 1658.6 mg/dm3 (norm - 500-4000/6000)

THINK: IN ONE TIME WITHOUT SELECTING THE FIRST DROPS! These are impressive results that are better than the results of double or triple distillation.

The colleague promised to continue to conduct comparative analyzes on oil seeds and meat products. There is a suspicion that the distillate is purified not only by fats, but also by proteins. He must find out.