-

4" To 6" Upgrade

@grim @crozdog thanks for your input. I'm a bit happier now knowing 380lt boiler with 8" Dash Pro can run spirit with 15kW, giving me loads of capacity... for now. Simple dimensions check, if you can help. What's the floor to superstructure opening height on the 380lt boiler? I've got the column (standard 3 plate config) at 1160mm and extra sections at 203mm from the web shop, so can work out what fits!

Stripping Run --> Spirit run: How to minimise wastage?What @crozdog said. I used one still for a long time and I would do three strips and then a spirit run. Remember on the spirit run to dilute your spirit down. So if you make 3 strips at 15l each you will have 45l of low wines. You should dilute that down with another 40 or 50 l of water and then do your spirit run.

4" To 6" UpgradeHi @punkin - I hear you on volume/work load! Can always charge less than 380lt, but mostly it'll be a full charge to maximise the capacity and volume output. Maybe smaller charge for trial runs, but I've got the 100lt/4" for that anyway.

Hi @crozdog - I'd prefer to go 8" if I think the powers enough, commercially it makes sense.

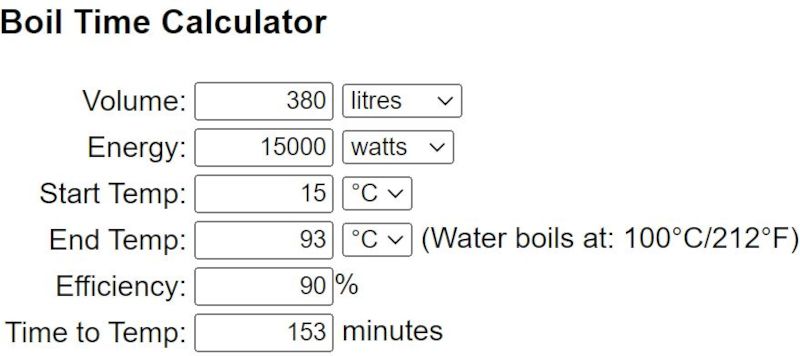

Heat up time is what it is really, max power available, how long will it take. We all work with that.

The only metric I have to select the column diameter is vapour speed.

Looked again at my existing 100lt/4"Dash (3 pro-cap plates), vapour speed is actually 16.03 on the run at 4.4kW. Your running 380lt/8", vapour speed is 12.75 on the run at 14kW.

I could do 380lt/8", vapour speed at 13.66 on the run at 15kW (leaving 5kW for the house load; max 20kW incoming main).

I do run my 4" quite hard then at 16.03 vapour speed, I use a good bit of reflux on this to maintain product flow. With 8" running at 15kW the heat to cooling ratio would be changed i.e. less reflux cooling at this lower vapour speed to maintain product flow. Is that the right thinking?

Really my big concern about going up to 8" was will I be able to power a decent enough flow rate, sound like I can albeit with a lower vapour speed than I'm used to on the 4".

Also 100lt to 380lt is almost quadruple, 4" to 8" is quadruple area. Roughly speaking then my heat-up/run time will be around the same for the same wash.

When I say sugar wash I mean molasses, demerara and granulated sugar blend, so there are some interesting things in the heads/tails and I do want to barrel age. Currently ageing on Still Dragon supplied oak woods, done one whisky cask aged for 8 months and it was outrageously good and sold out fast!

Stripping Run --> Spirit run: How to minimise wastage?Hi @crozdog, thanks for that! that is super useful info. A mate of mine was importing / exporting out of china, and we hopped on the import and grabbed one (think he paid about $3k inc onion & 4 plate column).

We're looking at making gin / vodka at the moment, so we're looking for a high alcohol content neutral spirit (we're using a chasing the craft wash recipe), which we'll water down to about %45 --> %50.

Stripping Run --> Spirit run: How to minimise wastage?Hey Folks,

I have ~80L of wash for a 100L still, which is now at the point it's ready to go through a stripping run. Using a wash calculator, it looks like we'll end up with about 15L of spirit post stripping run. This is my first time, so i'm guessing as i've got the reflux column running, we'll be able to collect (after foreshots / heads / tails) around 12L of usable spirit for spirit run.

Question is, given that i've got a 100L still with about 12L for the spirit run, what should i add back into the collection so i can re-run it through the still? i'm worried that if i pop that 12L in, its not enough to cover the element at the bottom and i'll bugger the heating element. From memory, i think it needs about 5 or 10L at the bottom of the still to cover the element.

thanks!!

4" To 6" Upgrade@SLOPEmeisteR Have a look at the calcs page

I used it to calculate your heat up time for 380l with 15000W & got an answer of around 2.5 hours to get a 10% wash to 90C @ 90% efficiency.

That page also has a vapour speed calculator ;-)

IMO the 380l is a perfect match with 8" columns. Remember diameter = speed. As a commercial operation, time = money. Smaller diameter = Longer runs = increased cost and lower production volumes :-(

I don't know why you say you can't get the power to run an 8". I have a 380l with 4 x 8" plates & use 21kw for heat up but cut back to 14kw for the run.

Good cuts come down to how you run the rig (eg power input, reflux ratio, timing, if you do a strip then spirit run etc). If you're going to be barrel aging you don't need the hearts cut to be as tight because you actually want a bunch of the congeners in heads (& late tails with rum) for flavour (but you won't get much of that on a sugar wash).

FYI, adding a few more plates will only take a little extra time to heat up. The longest time is getting the wash up to temp, getting the column to temp is pretty quick once the wash is boiling.

As you're operating in a pretty cold environment, don't forget you can insulate the boiler & column to improve thermal efficiency & hence overall performance of the rig.

4" To 6" UpgradeHi @grim,

Yeah I've got space and power limits to work within. I've converted my garage at home to a nano-brewery/distillery, fully HMRC licenced and selling product online and markets. I'm amazed at the quality (as are customers) I'm producing rum at on single pass through 3 plate 4" Dash, wow!

I put 12 kW solar on the roof last year, but that's only good for 8 months of the year, so working with limitation of single phase mains. The mains will do around 20 kW but I need to leave some for the wife to run the house! I recon 15 kW is a safe limit for the brewery/distillery.

This upgrade gets production capacity on rum alone into significant figures, with literally no overheads (no rent, rates, etc). As I approach capacity on the upgrade kit the business will be well placed to go for a much larger upgrade, commercial premises, and have the books to raise capital for investment. It's a plan to grow with as low a risk as possible.

Hence a bigger boiler at 380L than perhaps a 6" column requires, but I can't get the power for 8" and a 380L charge on 6" column will give a nice long run with long clear cuts I think. 380L boiler will never go a miss in a craft distillery. In the sunnier months (in Scotland, don't laugh!), I'll have up to 32 kW to play with depending on house load scheduling, this would let me run the upgrade still and my existing 100L 4" Dash... thinking maybe stripping runs on the 6" then run smaller still as a rectifier to produce vodka (might need to go 4 or 5 plates each on 4" and 6" to hit vodka).

4" To 6" UpgradeCurrent 100L boiler has 5 kW heating and takes around 2 hours to heat up my 4" Dash with 3 ProCap plates. Then around 4.5 hours at 4.4 kW with dephlegmator on pretty strong (cold Scottish water) I get a good steady flow through my cuts taking rum hearts around 81% from a 9.5% sugar wash. So I'm running with vapour speed around 15.9"/sec, right? I figure I want to replicate this as I scale up.

Thinking going with a 380L boiler with around 15 kW heating, this should take around 3 hours to heat up. I'm thinking a 6" Dash with 3 ProCap plates would take around 9.8 kW to run double flow rate through the cuts with the same vapour speed as my old rig at 15.9"/sec, right? But since the boiler volume is nearly 4 times bigger the time from heat up to end of tails will now be double the old rig, around 8 to 10 hours. Is my thinking right?

If I want to run more plates, say 6 or 8, would the total 15 kW give me enough headroom on power to push up the extra plates and maintain the product flow rate?

How many plates would I need on the new rig to make vodka, would 8 be enough and would the headroom of 15 kW of power be enough to push this through the plates with a reasonable product flow rate?

Plates and power, the balance of life!

I Love Obfuscation ProofingIf you ever hear me say that you know I've been kidnapped. I was doing Limoncello today. Just about done and the sugar does its normal thing. Now I have to clean up this disaster. Luckily I found that if I let it soak in PBW for a day or two it's not that hard to clean. It's still a huge mess though.

In the photo everything you see that is black solidified almost instantly. It smells horrible to boot. Yay me.

Rotovap

RotovapAdding "heads" back in to make the finished de-alcoholized product is absolutely critical for the aromatics and lighter flavors, otherwise the finished product is flat/bland. This product absolutely needs to be kept very cold, and is not stable for more than a few weeks. The esters will disassociate back into acids as the reduced alcohol content throws off the equilibrium.

Have played around with concentrating the flavor of bourbon as well with this. Where we take a bottle, extract the heads portion, and then remove all the water and alcohol to form a thicker concentrate, and add both of these back to an unaltered bottle (less a little volume).

It's interesting, but more isn't always better, lots of these were bitter oak bombs. It's kind of like breaking off a piece of the "sap" off a leaky large barrel and tasting it.

I've never tried fractionally distilling an entire bottle. Breaking vacuum with every fraction is very time intensive, would probably take me half a day of babysitting to break 750ml into 15 50ml fractions. I know they make a 'cow' for the Buchi, but I've never seen one come up for sale on eBay.

[USA/WA] Sale: 3 Pieces 6" x 6" x 3" Stainless Steel Sight Glass Union TeeHello,

I am selling (3) of StillDragon 6" x 6" x 3" Stainless Steel Sight Glass Union Tee. They came to me through some wine stainless steel stuff sale as not used. They were kept in indoor storage for about 5 years until I found it a week ago now they are on sale.

Each unit comes with glass "windows" - you get what you see on pictures. Nothing else is there.

They are sold at StillDragon for $245 each.

They are yours for $400 total for all (3) plus reasonable shipping cost.

Separate Boiler / Columns

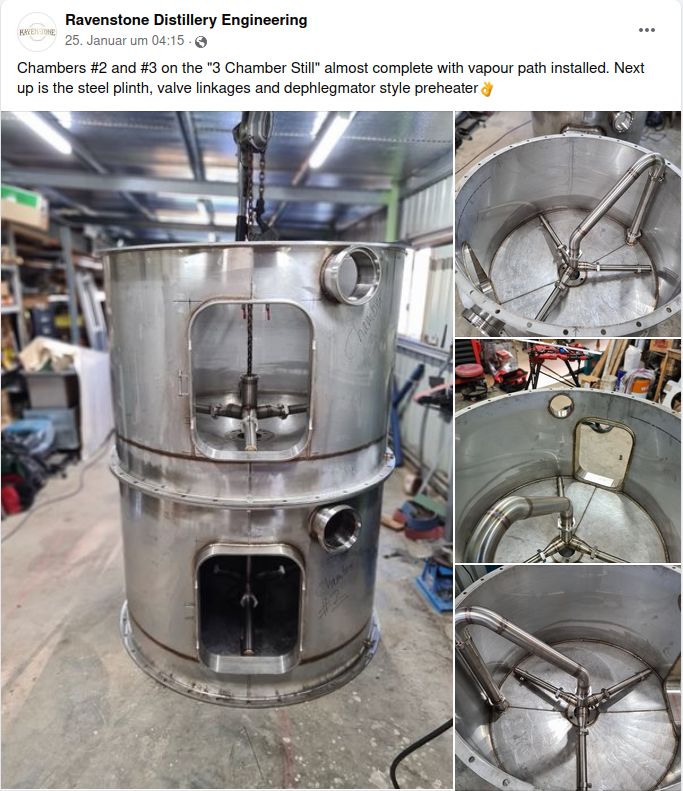

Separate Boiler / Columns 3 Chamber Still

3 Chamber StillAustralian distillery gonna get a 3 chamber

High Ester Still BuildHigh Ester Still Build

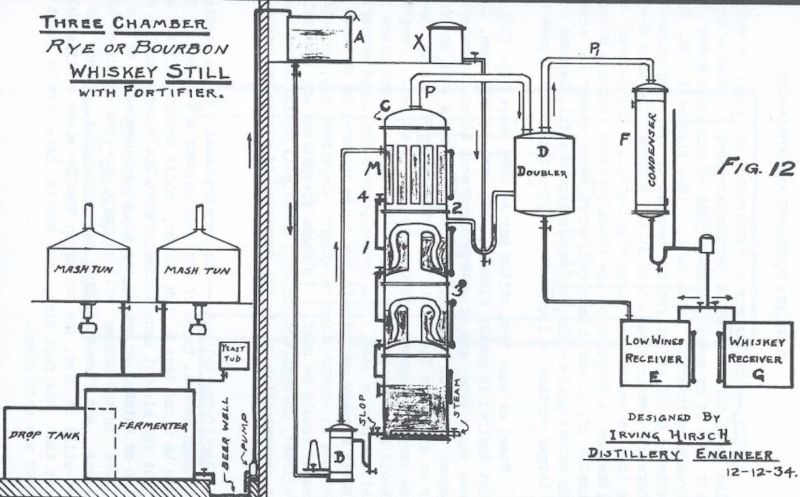

High Ester Still BuildHigh Ester Still BuildHold on, Hirsch designed the 3 chamber too?

High Ester Still Build

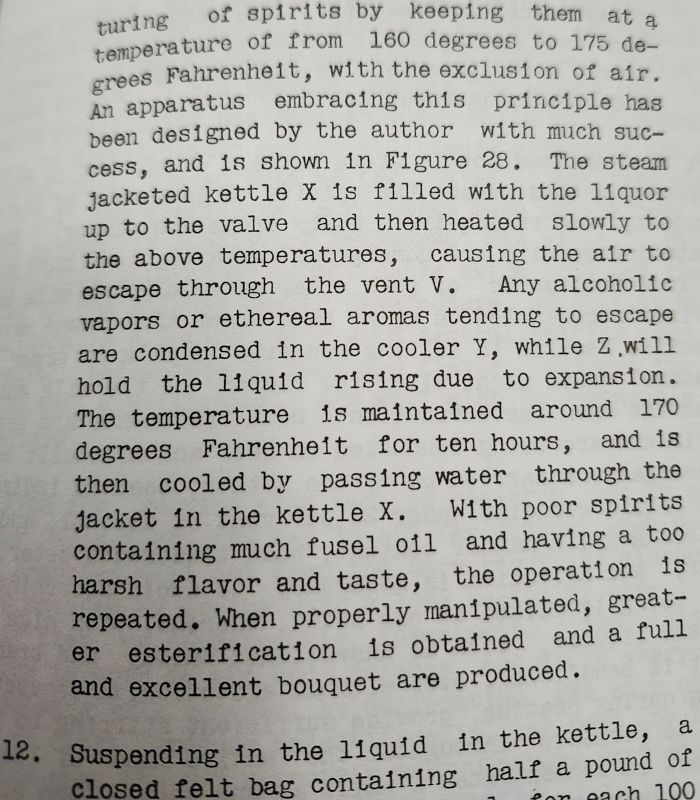

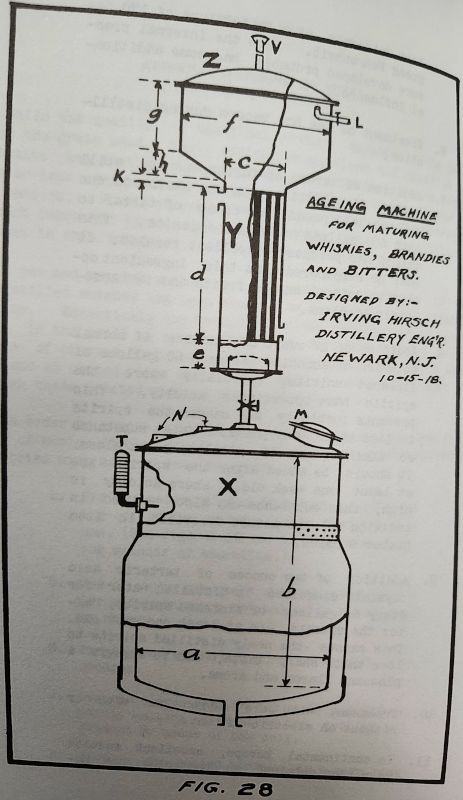

High Ester Still BuildHey @SingleMaltYinzer, i know this isn't what you had in mind but I found this in Whiskey, Brandy, and Cordials and thought you'd dig this...

It's their rapid aging idea from 1918, I honestly don't know what kind of effects it would have on a spirit aging wise, but it's basically just a big Fischer esterification still.

Coffee Liquer

Coffee LiquerWent digging because this sounded good: Luna's kahlua

DonMateo's Distillery ShedThanks mate. Here are a few more fotos. The first is the highly specialised front end loader as still removal crane thingy, the next is yours truly to give an idea of size of this thing and the final is a welding fotos for the equipment guys, which is most of us. The guy with the beer gut hooking up the lifting sling is Raul my gardener. I was going to take a gardners crack foto but that would have been a step too far.

DonMateo's Distillery Shed

DonMateo's Distillery ShedWell I finally received my stripping still today. My mate took 58 months to make it. The final boiler is very nice. But dont do what I did. Buy SD gear. Then you wont have to wait 5 years for a peice of gear. Its a 1300l strip with 6 element ports, an 8 " condensor that has 25 copper cooling coils. All local manufacture. I did the design myself one even when I was with my mate bent on bad whiskey.

GNS Continuous Still?

GNS Continuous Still?Just looked at some of those older threads, those guys were talking about 408 watts per gallon of feed per hour, not per minute, which I think explains it. For 2 gallons a minute, that's 2 * 60 * 408 = 49kw. Now we're cooking.

I have a tube in shell boiler that came out of a Millipore steam distillation purifier skid unit that I was experimenting with for building one of these. It's built for steam feed, and to boil 100% of the feed in one pass.

I'm not joking when I tell you that thing can easily consume every single BTU of our main boiler to be able to boil off a few gallons a minute (single digits). We're talking way more than 150kw, but there was no heat recovery in my testing.

One of my favorite tests was trying to build a continuous gin still off the vapor feed. Take a feed from a barrel of GNS and a barrel of water. Boil them off at the desired ABV. Push that vapor through a set of two baskets (with a valve to direct the vapor feed). Turn that baby on and just keep changing baskets until your swimming pool is full of gin.