Welcome!

Be part of our community & join our international next generation forum now!

Categories

In this Discussion

- CothermanDistilling March 2016

- grim March 2016

- jacksonbrown March 2016

- jbierling March 2016

- Moonshine March 2016

- Myles March 2016

- richard March 2016

- Smaug March 2016

Whiskey & Vodka in one Column

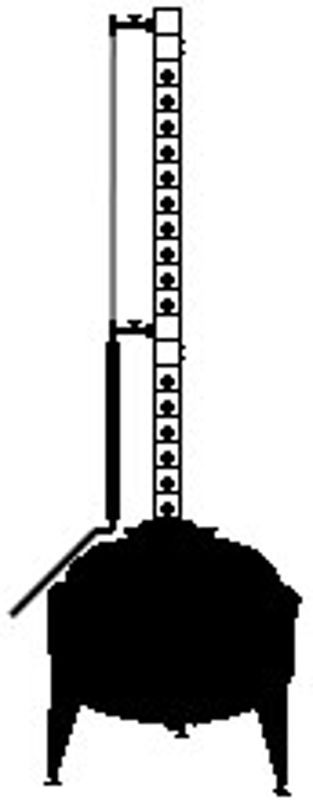

Standard 8" SD parts, except for diaphragm valves at the takeoff points. The top top valve is mainly there just to maintain a consistent distance for the down column and would remain open. Two deflegs and 4" condenser hanging. This is about 18' high.

Thoughts?

WhiskeyVodkaColumn.jpg

313 x 800 - 17K

Comments

Do it all through all plates but just adjust the reflux ratio. I don't see the point. Also why diaphragm valves?

Good question. Anyone do whiskey through 16+ plates?

I thought there might be clearance issues for a normal ball valve handle. I currently don't have any diaphragm valves. What's the downside?

Are we talking this scenario ??

Downside is price. You'll need to get them in a tolerant material. I don't understand 'clearance'. Shouldn't make a diff if you position it right.

Are you talking about the valve seat or an actuator?

Its one good reason for plate disable devices. Start with just a few plates in use for the whisky hearts cut, then bring in all the others, and finish the run for the second product.

Don't understand that second photo - parrot appears positioned to allow for drinking right off the still.

@jbierling - would make more sense to move the valve down to the bottom of the vapor pipe, near the other valve - or replace with a 3 way.

That's for showering, obviously. :D

Your Place to be >>> www.StillDragon.org <<< Home of the StillDragon® Community Forum

Knightside runs a similar setup. No valve at the top.

The whiskey take off branch has a dephlegmator just above as a safe measure to insure the vapor takes the path of least resistance. But I'm not sure the dephlegmator is necessary.

StillDragon North America - Your StillDragon® Distributor for North America

Notes from someone who does this now but by moving TC pipes ... and disassembles one of his 3 8-plate 8" CD sections to make a 3-4 plate version..

Like @Myles said - If you have more than 3-4 plates on the bottom, you will not have your 'whiskey'.... The US requirement is "produced at less than 160 percent proof" (average of collected run) So this is a GREAT argument to bring up plate bypass... (yes, "light whiskey" and "whiskey from malt" can be over 160)

If you also do stripping runs in this, you will ABC (always be cleaning)... only put clear stuff in it!!! EVER!!!!

I believe, with my experience on such a system, that the following would be a good protocol:

fill with low wines and late heads from previous W run compress fores and some early heads in either V or W mode take late heads in W mode and save them for future W run take middle cut hearts in W mode and save for cooperage add in late hearts and convert to V mode stabilize and take 190 proof take 190 hearts and save for making vodka reduce reflux and collect late 180+ hearts and save for future V run (even with 24 plates, 184 is nearly 10x as fast as 190)

add this to a continuous stripper, and you could make W and vodka every day.... although TTB 'batch record-keeping' might be a nightmare...

We are averaging about 140-145 hearts cut with 4 plates, single pass, relatively fast take off. I think if you pushed it fast enough, you could do 5 plates and still stay under 160, but will probably be cutting it close. 6 - no way. If you are stripping, I think 3 plates is going to be pushing it.

how cruddy is your still doing one run like that?

The more I read and based on what I have tried in the past, I am absolutely convinced of the benefits in having two boilers.

If you can, never put wash in your spirit boiler. Only put low wines in it.

@grim, The main reason I had the valve on top was to make sure that the standoff was exactly the same between the bottom and the top. If I had a piece of tri-clamp pipe that matched the length of the valve exactly, that would work. A three-way valve would work too and perhaps be the best option.

I do whiskey right now with five plates and stay just under 160. Perhaps six plates is too much, but it seemed to match the length of the 4 inch condenser better. Could probably put a blank in there rather than a plate.

Well it would be nice to have a separate still for every type of spirit I make but practically I'd like to be able to do both spirit and wash in one still.

Oh that is custom pipe no matter what, that pipe length is critical - heck even the gasket material is going to make an impact to that pipe length if you are talking about 12 gaskets on the opposite side.

It's not too bad, we get a little bit of buildup on the glass after about 4 back to back runs of the same product. Would absolutely CIP between product types.

Did you ever get any kind of CIP setup installed, or are you breaking down to clean? We've never broken down, and don't plan to anytime soon.

You'll find you're getting a few hundred watts of reflux just through the wall of the column cooling in the air.

With adequate insulation and zero flow to the delph it should run like a pot. It just comes down to the quality of the insulation on the column.

agreed 100%

Yesterday I ran PBW @ 180°F in my 380L for 45 min and it took THREE TIMES of doing that and still needed to scrub with a long brush... (luckily I only use 5 gal and a sprayball)

@grim - I don't really break down, I insert the CIP stuff through the 2" fitting on the top and put a 6kW rims tube on the drain and then connect a pump...

No question the boiler gets dirty, but assuming you do basic cleaning after each run (caustic, water, acid, water) does that make its way into the distillate?