Welcome!

Be part of our community & join our international next generation forum now!

Categories

In this Discussion

- Anavrin July 2015

- dad July 2015

- ElectricEd July 2015

- grim July 2015

- jacksonbrown July 2015

- Telluride July 2015

- TheMechWarrior July 2015

Simple Continous Still

Hello All,

There has been a lot of discussion about continuous stills and it is all very interesting. I have an idea, that most people with a StillDragon, can do some simple modification to make their StillDragon a continuous still. Can you all provide some feed back.

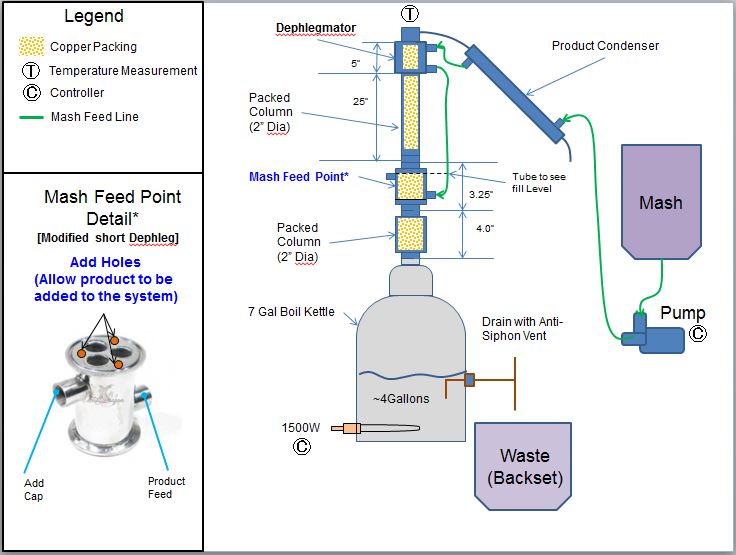

The concept is to have as little additional parts to modify the still to make it into a continuous still. The only modified part is the product feed, which is a dephlegmator with holes drilled on the top. This allow product to be introduced into the column. I made some simple diagrams below of the concept.

Also the mash works as the cooling medium in the condenser and dephlegmator, this also pre-heats it before it enters the column.

Let's discuss.

Comments

Simple but your feed rate is now governed by condenser flow requirements.

Based on your wash temp, you may find you need a higher flow rate to cool the PC and RC than your column is able to strip.

Could you balance it? Maybe, but it would probably take quite a bit of trial and error.

I agree, if you have a needle valve on the feed into the top dephlagmator and another needle valve on a return line to your wash you can set the back pressure in the system and still be able to control the cooling processes. Here's the basic layout to my system, it could easily be modified to suit yours.

BTW, the pump you choose must be able to run continuously, so get one with an induction motor and uses an impeller, don't get a positive displacement pump unless it has an adjustable pressure bypass, they can over heat and switch off if they have heat switch or sieze if they don't. A friend's setup uses a pump from a commercial coffee machine attached to a 1/2 horsepower washing machine motor. It can run for weeks and not get the slightest bit warm.

These little suckers use an induction motor but the flow rate would be too high. Any idea on how you'd regulate one of these?

I'm not aware of a VSD small enough for the job.

Iwaki Co. Single Phase Induction Magnetic Pump Motor MD-15R-200N 2600RPM USG @ eBay

I think your feed into the column could just be a tee, couldn't it?

Like grim said, getting that system to work is a balancing act.

I tried it and gave up for a few reason.

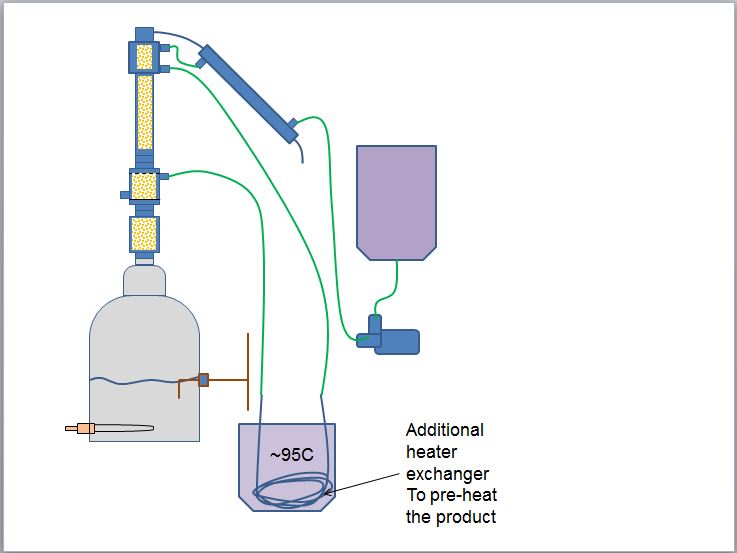

If your feed ABV is to high then it'll need more cooling capacity than the feed can give. Adding a rectification column above the feed point to pull out excess water will help a lot though. Using super loose packing and getting good control of the feed is extremely important from what I found. I also had another shotgun on the bottoms to add more heat to the feed after in goes through the PC. This meant the only real heat source was from the boiler, all the preheat was regen.

Mine went to shit when I tried it on a molasses wash though.

A degassing/foaming step is going to be a must depending on what you plan on pushing through it.

I use a Chemical Metering Dosing injection Pump for metering chlorine into my water system. They are fairly reasonable and can be rebuilt cheaply when they do fail. You can control the pressure, timing and duration of the spray, thus varying the amount sprayed.

Problem is, they will not handle any solids...some of them use SS or glass balls for the op valves.

I bought used pumps for ~$100 off ebay and a rebuild kit is ~$30 from a plumbing supply house. I have had one go for a year and others for five years. They are very easy to rebuild, but I always have a spare ready.

DAD... not yours.. ah, hell... I don't know...

LMI? Those a nice pumps.

If you can deal with around a liter a minute, Cole Parmer makes some very nice variable speed teflon diaphragm pumps.

This is a pump I've been looking at to make a recirculating carbon filter, it's pump head is all stainless steel and its magnetically coupled so you can just run it and restrict the flow with a valve to whatever flow rate you want, I'm no expert in pumps, just thought I'd throw it in the mix in case it's of any use for this project.

TD5 - SS Mag Pump @ BrewBuilder

I wouldn't buy that pump unless I knew what the seals were made of.

High proof, ideally ptfe.

The pumps in commercial coffee machines have a 'pressure bypass' on them. You can adjust from 0.5 bar to a bit over 15 bar. They provide exactly what you need and give a consistent pressure. You can also get them from bar dosimeters that provide softdrinks. There are 5 of these pumps in them. Just lookin metal scrap yards and you'll eventually score. If you want to buy one new they are about $180 and you'll still have to fit them to a motor.

Jim heising did something with 1500w and only needed his mash to cool on his PC, I dont think he had any reflux, it was just ceramic rashig rings and basically 2" triclamp fittings with a band heater, preheated on a condenser then entered the column from the top, slow feed of 3.5 to 4 gph:

https://www.youtube.com/watch?v=QmcvEhur8ek