-

GNS Continuous Still?

My main bain marie still is 330l but when i run it with 220l i run it with 3 elements pushing about 6kw each. On a 220l batch it will heat up in about 45 mins and strip in about 2.5 hours. A 330l run will take about an hour and 15 mins depending on the abv and take 3.5 to 4 hours to strip. Again depending on the abv and if it pukes and inhave yo slowndown the first 30 mins.

GNS Continuous Still?Wow, I was way off.

I got the 408w pg ph based on other continous threads.

GNS Continuous Still?@Bolverk said: To run a 55g barrel in 6 hours (using 408w pg ph) you'd only need 3.7kw.

Based on playing around with this design, I can't see how you could do that with such little power.

The latent heat of vaporization of ethanol is 340btu/lb, at 6.8 pounds a gallon for ethanol, we're talking 127,000 BTU's or 37kw total, just to take it from near boiling to vapor. So for a 6 hour run time, you'd need 6.2kw, and that's just vaporization, which doesn't account for heating from ambient to boiling point.

Now sure, you'll recover some energy with the preheater, but there are going to be losses on the piping, column, etc.

I tried to do the math in my head the other day thinking 30-40kw to achieve the 2gpm they state, but it's probably even more than that.

GNS Continuous Still?Ok single pass boiler.

Yeah but who says you have to run it that fast.

To run a 55g barrel in 6 hours (using 408w pg ph) you'd only need 3.7kw.

GNS Continuous Still?Go back and do the math required to heat and vaporize ethanol, and work backwards from your power input to see what that means in terms of feed rate.

I don't have a calculator handy, but I'm guessing you'd be talking somewhere in the ballpark of 40kw to support 2gpm, assuming zero heat recovery (which isn't the case), so maybe closer to 30kw?

That thing isn't a reboiler, it's a single pass 'boiler', in 1 minute, 2 gallons of feed is heated and completely vaporized.

GNS Continuous Still?There is zero material difference between 40% ethanol and 95% ethanol in terms of flammability or explosivity at or near it's boiling point.

GNS Continuous Still?Electric element would work, but you would need additional level sensors to prevent the element from running dry, and if you really built this thing using all classified (xp) electrics, it would be expensive. Your feed rate will be entirely determined based on how fast you can vaporize 100% of your feed.

Unfortunately, you absolutely can not proof down with this approach. Your product will be taken off as exactly the same proof as your input. If you proof to 40%, your distillate can not be considered vodka or neutral spirits, it's going to come off at 40%.

Would also require significantly more energy to heat and cool the greater volume.

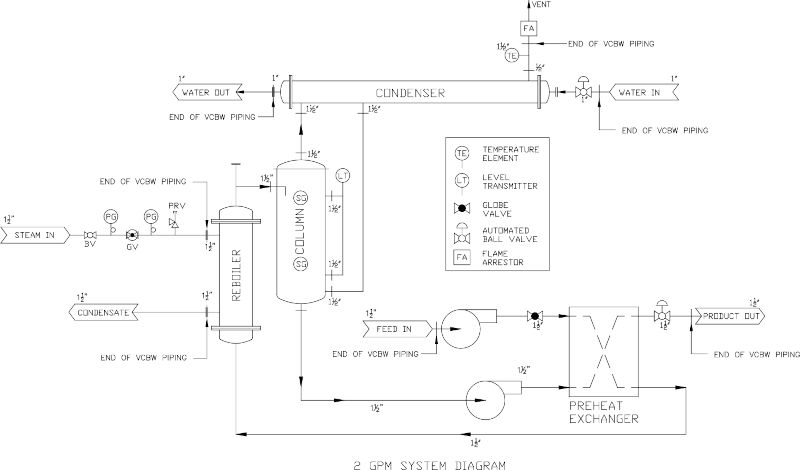

GNS Continuous Still?Thanks @grim, I've seen this drawing and it makes WAY more sense now knowing that's its to rerun GNS (not produce GNS like how I read it).

So say you don't have the $45k for the model above, and wanted to run it as an electric element driven thermosyphon reboiler. Do you think you could proof down to say 40% or would you need to go lower?

GNS Continuous Still?No dilution, run full strength, the only thing you'll be taking off is heads (which can be done as vapor).

A well known manufacturer sells a system like this.

Uses a very, very simple approach. At 2 gallons feed rate a minute, it's a little rocket ship.

Work with extracts & canning issuesOne wonders from a cost perspective, for viability of canning a 100ml can size.

I saw this can filler (didn't include seaming) that looked quite interesting at Euro 10,950.-

No Topic ThreadMorning and merry Xmas to all

Looking for suggestions for future production

For Christmas I made some Limoncello for my brother. It came out really good and is real tasty. The only issue is a black type residue on the surface. Now I understand this to be excessive lemon oils coming out of solution.

When I bottled, I was away and used a basic coffee filter to filter out. Obviously not fine enough and ought possibly have used a depth filter for oils.

In any case, any recommendations for the future.

Cheers.

MERRY XMAS 2023

MERRY XMAS 2023Merry Christmas everyone!

MERRY XMAS 2023

MERRY XMAS 2023Ho Fuckin' ho

3 Chamber Still

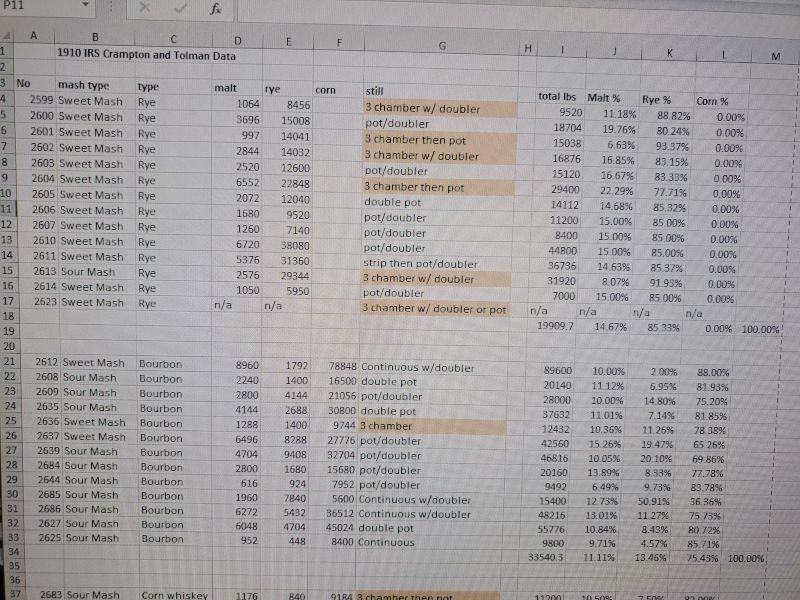

3 Chamber StillHere's there breakdown of who was using what on the Crampton and Tolman paper.

The use of a 3 chamber for ryes isn't nearly as prolific as we thought, just under half of the rye submissions were made on a 3 chamber.

3 Chamber Still

3 Chamber Still@Smaug said: On the drawing here (2000L chambers), the preheater coil has 62.8 sq. ft. (5.8 sq. meters) worth of surface area if my math is correct.

The piping on the left-hand side is the vent that allows for smooth liquid transfer.

We will incorporate automatic valves and and PLC control to handle all of the liquid transfer duties.

Hello @Smaug,

I hope you're doing well. I've been following your discussions about the distillation setup and find your insights extremely valuable. I have a couple of questions regarding your setup, particularly about the coil and its heat transfer capabilities.

I understand the importance of not having all the ethanol condense inside the pipe, aiming for a condensation rate of about 10-15%. This is why I'm curious about the surface area you've estimated for your coil. Could you kindly share what size of pipe you're using for the coil? Is it a 2" inch pipe? Given the surface area, it seems like the coil in your condenser would be around 1387 meters of pipe. How did you arrive at this specific size?

Also, in my design, I haven't incorporated pipes on the side for moving the wash. Instead, I've opted for a conic bottom with a 4-inch knife valve for control, positioned at the side. I'd love to hear your thoughts on this approach.

Thank you for taking the time to read my query. Any insights or advice you could offer would be greatly appreciated.

[SOLD] Sale: Bulk MolassesI have 1400kg of refinery cane grade molasses for sale.

Based in the UK.

Smooth with no lumps, ready for rum fermentation without any additional processing.

Around 55% sugar content.

Purchased from United Molasses in the UK.

£0.35 per kg, so £490 for 1400kg. The IBC is free.

[USA/MO] Sale: 8" Bubble Cap 16 Plate Distillation Column

[USA/MO] Sale: 8" Bubble Cap 16 Plate Distillation ColumnColumn was used for GNS (100% wheat) production - equipment is now idle and I'm motivated to sell it.

Purchased new in 2016 and was used for 4 years.- SD ProCap Plate Assembly

- All clamps, gaskets, flow directors, etc

- 8" Column Base

- 8" Stainless Steel Dephlegmator

- Reflux Float Switch

- Taco Reflux Pump

- Reflux Pump Controller

8" - 16 plate reflux distillation column for sale: $11,000

Located in Kansas City, MO, USA. Buyer coordinates shipping.Email me for more information: derrick@liftedspiritskc.com

Big Ass Fan Company Swamp Cooler For Sale

Big Ass Fan Company Swamp Cooler For SaleHey gang, This thing is brand new.

Here is the skinny: I hired a guy that was not nearly as helpful as he represented himself qualified to be. Without my authorization the dude purchases this Big Ass swamp cooler without the understanding that swamp coolers don't really provide any real value indoors in the humid Florida summertime. To add insult to more stupidity, the dude also assumed it would be "cool" (see what I did there?) to run the swamp cooler with the bay doors shut,,,,in a warehouse that relies pretty heavily on the use of cardboard boxes for much of the organization of components. And of course the ultimate frustration was that I allowed myself to debate with this person on why swamp coolers are not the best solution in humid, tropical environments when one is trying not to add additional moisture content to one's paper products.

Anyhow, it is brand new and has not been at all used. I can ship it anywhere you like. The dimensions are: 62"W x 72"H x 28"D.

It has locking castors mounted on the under side and rolls very nicely. I (evidently) paid $3499.00

Make an offer.

Pressure relief valve three chamber still

Pressure relief valve three chamber stillI think @Smaug's comment - opening the anti-vacuum port to allow the contents to drain, is probably the more important design aspect.

If you are concerned about pressure issues, just install a PRV in each section, done, call it a day.

Actively regulating pressure? I don't think that's the case, and I've never seen any still design that needs to operate at some bleeding edge of pressure that would require some kind of (wasteful) active regulation.

I have a tank vacuum break/vent valve similar to that on my HLT that looks very, very similar to that:

It has a very low weight spring so that it can either vent or vac, but otherwise has a light seal to keep out dust, bug, or otherwise from getting in.

Pressure relief valve three chamber stillHey @Bolverk you are taking about that 2" stainless steel pipe (red selection) connected to the top of each chamber with the valves or you referring to that probably 1" pipe coming from the bottom chamber only at the back (blue selection), because if its the blue he is just using for bottom chamber as I was thinking because is were you are injecting live steam.