-

Separate Boiler / Columns

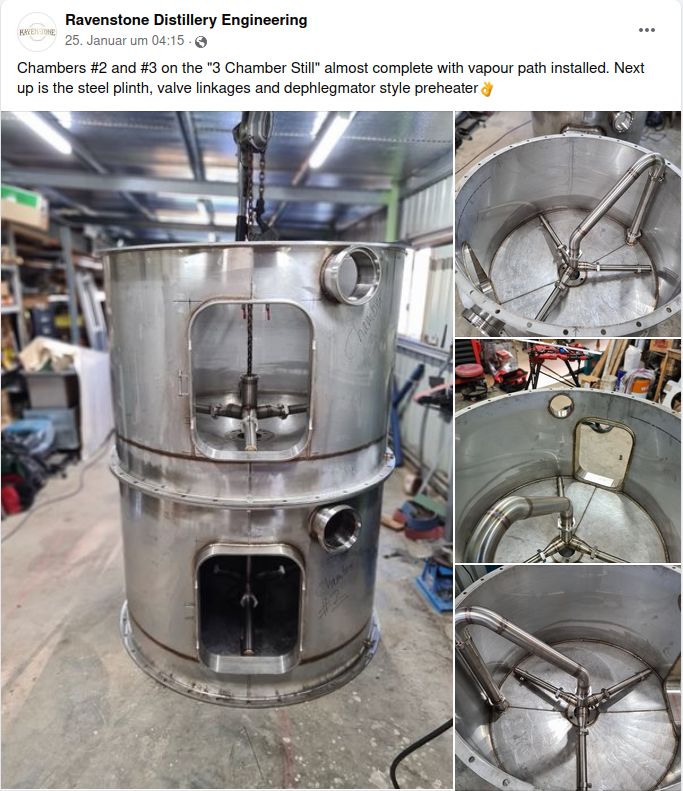

3 Chamber Still

3 Chamber StillAustralian distillery gonna get a 3 chamber

High Ester Still BuildHigh Ester Still Build

High Ester Still BuildHigh Ester Still BuildHold on, Hirsch designed the 3 chamber too?

High Ester Still Build

High Ester Still BuildHey @SingleMaltYinzer, i know this isn't what you had in mind but I found this in Whiskey, Brandy, and Cordials and thought you'd dig this...

It's their rapid aging idea from 1918, I honestly don't know what kind of effects it would have on a spirit aging wise, but it's basically just a big Fischer esterification still.

Coffee Liquer

Coffee LiquerYeah I destroy'd myself on 19% Aguardiente once. Snuck me when I was looking the other way.

Coffee LiquerWent digging because this sounded good: Luna's kahlua

DonMateo's Distillery ShedThanks mate. Here are a few more fotos. The first is the highly specialised front end loader as still removal crane thingy, the next is yours truly to give an idea of size of this thing and the final is a welding fotos for the equipment guys, which is most of us. The guy with the beer gut hooking up the lifting sling is Raul my gardener. I was going to take a gardners crack foto but that would have been a step too far.

GNS Continuous Still?

GNS Continuous Still?I was going to ask about this is a different way... so there's a local distillery that claims to pot still their vodka 7 times in order to get their neutral... but even if they are diluting down the their high wines to 40%, they'd never hit 190. How is it you think they are getting away with it?

GNS Continuous Still?@grim said: Unfortunately, you absolutely can not proof down with this approach. Your product will be taken off as exactly the same proof as your input. If you proof to 40%, your distillate can not be considered vodka or neutral spirits, it's going to come off at 40%.

I don't have a horse in this race, but while vodka needs to be distilled to 190+ proof, I don't see a stipulation that vodka needs the last distillation to be 190+. Now, maybe we're talking about class changing, but that's something else that may be legally significant but not actually end product significant.

Good feedback everywhere else as usual.

DonMateo's Distillery ShedWell I finally received my stripping still today. My mate took 58 months to make it. The final boiler is very nice. But dont do what I did. Buy SD gear. Then you wont have to wait 5 years for a peice of gear. Its a 1300l strip with 6 element ports, an 8 " condensor that has 25 copper cooling coils. All local manufacture. I did the design myself one even when I was with my mate bent on bad whiskey.

What would YOU do?

What would YOU do?I used it and it did not like how slow it was below 80F, but other than that I liked it.. granted I did pitch it into thin mash of 1.070 at 1gram/gallon or so and then at high krausen I added the thick mash that would have taken it to 1.170-1.180 if I did it initially...

GNS Continuous Still?Just looked at some of those older threads, those guys were talking about 408 watts per gallon of feed per hour, not per minute, which I think explains it. For 2 gallons a minute, that's 2 * 60 * 408 = 49kw. Now we're cooking.

I have a tube in shell boiler that came out of a Millipore steam distillation purifier skid unit that I was experimenting with for building one of these. It's built for steam feed, and to boil 100% of the feed in one pass.

I'm not joking when I tell you that thing can easily consume every single BTU of our main boiler to be able to boil off a few gallons a minute (single digits). We're talking way more than 150kw, but there was no heat recovery in my testing.

One of my favorite tests was trying to build a continuous gin still off the vapor feed. Take a feed from a barrel of GNS and a barrel of water. Boil them off at the desired ABV. Push that vapor through a set of two baskets (with a valve to direct the vapor feed). Turn that baby on and just keep changing baskets until your swimming pool is full of gin.

GNS Continuous Still?My main bain marie still is 330l but when i run it with 220l i run it with 3 elements pushing about 6kw each. On a 220l batch it will heat up in about 45 mins and strip in about 2.5 hours. A 330l run will take about an hour and 15 mins depending on the abv and take 3.5 to 4 hours to strip. Again depending on the abv and if it pukes and inhave yo slowndown the first 30 mins.

GNS Continuous Still?@Bolverk said: To run a 55g barrel in 6 hours (using 408w pg ph) you'd only need 3.7kw.

Based on playing around with this design, I can't see how you could do that with such little power.

The latent heat of vaporization of ethanol is 340btu/lb, at 6.8 pounds a gallon for ethanol, we're talking 127,000 BTU's or 37kw total, just to take it from near boiling to vapor. So for a 6 hour run time, you'd need 6.2kw, and that's just vaporization, which doesn't account for heating from ambient to boiling point.

Now sure, you'll recover some energy with the preheater, but there are going to be losses on the piping, column, etc.

I tried to do the math in my head the other day thinking 30-40kw to achieve the 2gpm they state, but it's probably even more than that.

GNS Continuous Still?That larger one is a behemoth at 5-10 gpm

GNS Continuous Still?Go back and do the math required to heat and vaporize ethanol, and work backwards from your power input to see what that means in terms of feed rate.

I don't have a calculator handy, but I'm guessing you'd be talking somewhere in the ballpark of 40kw to support 2gpm, assuming zero heat recovery (which isn't the case), so maybe closer to 30kw?

That thing isn't a reboiler, it's a single pass 'boiler', in 1 minute, 2 gallons of feed is heated and completely vaporized.

GNS Continuous Still?Electric element would work, but you would need additional level sensors to prevent the element from running dry, and if you really built this thing using all classified (xp) electrics, it would be expensive. Your feed rate will be entirely determined based on how fast you can vaporize 100% of your feed.

Unfortunately, you absolutely can not proof down with this approach. Your product will be taken off as exactly the same proof as your input. If you proof to 40%, your distillate can not be considered vodka or neutral spirits, it's going to come off at 40%.

Would also require significantly more energy to heat and cool the greater volume.

GNS Continuous Still?Howdy all,

So i just had a thought... tell me if this is stupid please...

OK so I've read that a lot of folks redistill their GNS for vodka so its made in house.

My question, is it dumb to think that a pretty simple continous still with a few rectification plates at the top could be made to run GNS through? I mean there are no solids to deal with, minimal anything other than water and ethanol... hell would you even need to make cuts since it's already fully rectified?

Typically stripping stills would see a 8-12% beer, what's would you proof your GNS down to if you ran this setup?

Thanks,

BWork with extracts & canning issuesCheck out some of the folded/deterpinated citrus oils in lieu of straight extracts (or just rotovap your own). They are largely colorless and much more stable.

Short of it is, they are lower in limonene and other monoterpenes than traditional extracts, this allows more of the citrus varietal character to shine. Straight extracts are really hard to discriminate (citrus, citrus, citrus, citrus). With the 5x-10x, one quick smell and you can tell exactly.

This doesn't replace the 'juice' consideration in a cocktail (some of the terpenes are required), but they can be used in conjunction to add some amazing aroma and top-note that really feel lighter, fresher, natural, and higher quality. Also worth noting that folded oils are more stable and more soluble, as it's usually the terpenes that cause solubility issues (but concentrations are significantly higher, so you can not use folded oils as a 1:1 substitute).

There are also significant regional considerations for the flavor and aroma quality (lime is famous for this).