-

GNS Continuous Still?

Go back and do the math required to heat and vaporize ethanol, and work backwards from your power input to see what that means in terms of feed rate.

I don't have a calculator handy, but I'm guessing you'd be talking somewhere in the ballpark of 40kw to support 2gpm, assuming zero heat recovery (which isn't the case), so maybe closer to 30kw?

That thing isn't a reboiler, it's a single pass 'boiler', in 1 minute, 2 gallons of feed is heated and completely vaporized.

GNS Continuous Still?Electric element would work, but you would need additional level sensors to prevent the element from running dry, and if you really built this thing using all classified (xp) electrics, it would be expensive. Your feed rate will be entirely determined based on how fast you can vaporize 100% of your feed.

Unfortunately, you absolutely can not proof down with this approach. Your product will be taken off as exactly the same proof as your input. If you proof to 40%, your distillate can not be considered vodka or neutral spirits, it's going to come off at 40%.

Would also require significantly more energy to heat and cool the greater volume.

GNS Continuous Still?Howdy all,

So i just had a thought... tell me if this is stupid please...

OK so I've read that a lot of folks redistill their GNS for vodka so its made in house.

My question, is it dumb to think that a pretty simple continous still with a few rectification plates at the top could be made to run GNS through? I mean there are no solids to deal with, minimal anything other than water and ethanol... hell would you even need to make cuts since it's already fully rectified?

Typically stripping stills would see a 8-12% beer, what's would you proof your GNS down to if you ran this setup?

Thanks,

BWork with extracts & canning issuesCheck out some of the folded/deterpinated citrus oils in lieu of straight extracts (or just rotovap your own). They are largely colorless and much more stable.

Short of it is, they are lower in limonene and other monoterpenes than traditional extracts, this allows more of the citrus varietal character to shine. Straight extracts are really hard to discriminate (citrus, citrus, citrus, citrus). With the 5x-10x, one quick smell and you can tell exactly.

This doesn't replace the 'juice' consideration in a cocktail (some of the terpenes are required), but they can be used in conjunction to add some amazing aroma and top-note that really feel lighter, fresher, natural, and higher quality. Also worth noting that folded oils are more stable and more soluble, as it's usually the terpenes that cause solubility issues (but concentrations are significantly higher, so you can not use folded oils as a 1:1 substitute).

There are also significant regional considerations for the flavor and aroma quality (lime is famous for this).

Work with extracts & canning issuesOne wonders from a cost perspective, for viability of canning a 100ml can size.

I saw this can filler (didn't include seaming) that looked quite interesting at Euro 10,950.-

Work with extracts & canning issuesThese are the little guys: 100mL Can @ Very Good Mfg

Work with extracts & canning issuesWe've done north of 15-20k to-go cocktails since covid (I need to tally the numbers again). I'm impressed with the number, but realistically, it's nothing in terms of volume.

This is, very very different from an RTD. We store refrigerated, we recommend refrigeration to customers. We make this on the tasting room side of the house, not the distillery. This is not sold via distribution, but tasting room only.

One thing that I personally think helped a lot, and this is a technique I would use going forward with an RTD model if we go there, and that's to pack smaller containers at a overall higher concentration.

Nearly all of our to-go cocktails are 'shake with ice'. Yes, this is a pain in the ass for customers, and you can not consume from the can. However, we like this, as it creates a bit more cocktail experience in the preparation and consumption. You need to drink from glassware (we like it this way). You do need some way to shake or at least stir on ice.

BUT, delaying the dilution like this keeps the alcohol concentration high and the acidity high, which helps with overall stability. From an appearance perspective, it also keeps the coloration more intense, so it's more appealing when you pour and shake. These are sold in glass, so you can see the product.

I'm starting to see more tiny cans on shelves. I'm not even talking about the smaller 8oz sleek cans, these suckers are like 150ml or smaller. To me, these are perfect, and have me starting to think about the RTD route again.

No Topic ThreadMorning and merry Xmas to all

Looking for suggestions for future production

For Christmas I made some Limoncello for my brother. It came out really good and is real tasty. The only issue is a black type residue on the surface. Now I understand this to be excessive lemon oils coming out of solution.

When I bottled, I was away and used a basic coffee filter to filter out. Obviously not fine enough and ought possibly have used a depth filter for oils.

In any case, any recommendations for the future.

Cheers.

MERRY XMAS 2023

MERRY XMAS 2023Merry Christmas everyone!

MERRY XMAS 2023

MERRY XMAS 2023Ho Fuckin' ho

Going to hate myself for barreling rum this high

Going to hate myself for barreling rum this highI got a 160 i put away in a 15 a couple years ago like that (it was kind of an accident tho..) need to inspect it...

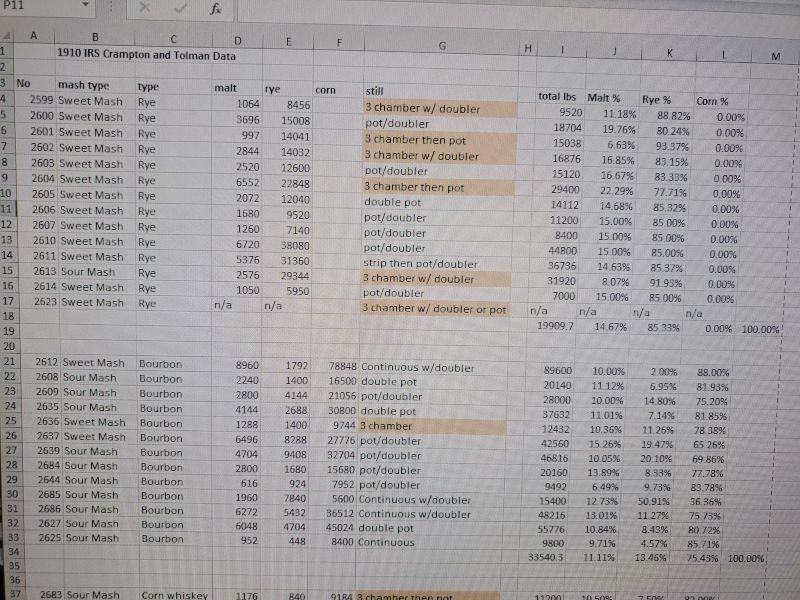

3 Chamber StillHere's there breakdown of who was using what on the Crampton and Tolman paper.

The use of a 3 chamber for ryes isn't nearly as prolific as we thought, just under half of the rye submissions were made on a 3 chamber.

3 Chamber Still

3 Chamber Still@Smaug since the 3 chamber is an oil extraction machine I would guess the amount of oil in corn could be a concen... it could be too oily? Although maybe it depends on the corn variety?

If you look at the Crampton and Tolman papers 1 of the 13 bourbon participants was making bourbon on a 3 chamber and 2 of the 3 corn whiskey participants were made on a 3 chamber.

3 Chamber Still@DMdistilling said: Thank you for taking the time to read my query. Any insights or advice you could offer would be greatly appreciated.

i wrote wrong number that coil at 2" pipe will be 33m lenghth no 1387m typyng mistake

3 Chamber Still@Smaug said: On the drawing here (2000L chambers), the preheater coil has 62.8 sq. ft. (5.8 sq. meters) worth of surface area if my math is correct.

The piping on the left-hand side is the vent that allows for smooth liquid transfer.

We will incorporate automatic valves and and PLC control to handle all of the liquid transfer duties.

Hello @Smaug,

I hope you're doing well. I've been following your discussions about the distillation setup and find your insights extremely valuable. I have a couple of questions regarding your setup, particularly about the coil and its heat transfer capabilities.

I understand the importance of not having all the ethanol condense inside the pipe, aiming for a condensation rate of about 10-15%. This is why I'm curious about the surface area you've estimated for your coil. Could you kindly share what size of pipe you're using for the coil? Is it a 2" inch pipe? Given the surface area, it seems like the coil in your condenser would be around 1387 meters of pipe. How did you arrive at this specific size?

Also, in my design, I haven't incorporated pipes on the side for moving the wash. Instead, I've opted for a conic bottom with a 4-inch knife valve for control, positioned at the side. I'd love to hear your thoughts on this approach.

Thank you for taking the time to read my query. Any insights or advice you could offer would be greatly appreciated.

3 Chamber StillFound another interview with Todd... slowly we'll start to understand how to drive this still.

Part 1

https://www.youtube.com/watch?v=sYGzyPXQjUI

Part 2

https://www.youtube.com/watch?v=7efKxyqaEWk

In part 1 Todd talks about ordering another one from Vendome, this one going to be 3x the size, itll do 6 barrels a day.

3 Chamber Still@DonMateo said: Thats what I thought. If I remember my hydraulics design classes from construction school. Its a vent stack with valves for each chamber. You will have to open them all prior to draining from one chamber to the next and they will be the last thing you close before turn the power on.

100%

[SOLD] Sale: Bulk MolassesI have 1400kg of refinery cane grade molasses for sale.

Based in the UK.

Smooth with no lumps, ready for rum fermentation without any additional processing.

Around 55% sugar content.

Purchased from United Molasses in the UK.

£0.35 per kg, so £490 for 1400kg. The IBC is free.

3 Chamber Still

3 Chamber Still@Smaug said: And the other side.

Hey @Smaug, I really like your design! I was wondering what the surface area of the coil is in the top chamber for the preheater. My still will be 1300mm in diameter and 900mm high. According to my simulation, I got around 0.95sqm for the coil. I plan to have it made with a 2-inch copper pipe that's 6m long, but since I think it will be around 2 turns, could you tell me what you're getting? This information would be very helpful.

Also, I have a question about the pipe coming from the sides. Is it used to control the vacuum pressure in the chambers? If so, how do you control the flow? Do you use solenoid valves or another method? Thanks, mate!

[USA/MO] Sale: 8" Bubble Cap 16 Plate Distillation ColumnColumn was used for GNS (100% wheat) production - equipment is now idle and I'm motivated to sell it.

Purchased new in 2016 and was used for 4 years.- SD ProCap Plate Assembly

- All clamps, gaskets, flow directors, etc

- 8" Column Base

- 8" Stainless Steel Dephlegmator

- Reflux Float Switch

- Taco Reflux Pump

- Reflux Pump Controller

8" - 16 plate reflux distillation column for sale: $11,000

Located in Kansas City, MO, USA. Buyer coordinates shipping.Email me for more information: derrick@liftedspiritskc.com