-

High Ester Still Build

Hey @SingleMaltYinzer, i know this isn't what you had in mind but I found this in Whiskey, Brandy, and Cordials and thought you'd dig this...

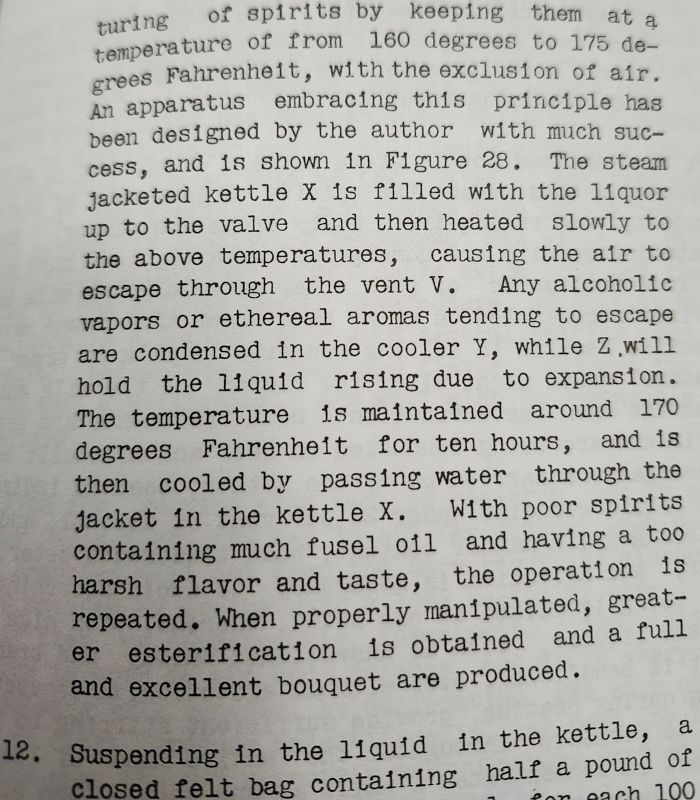

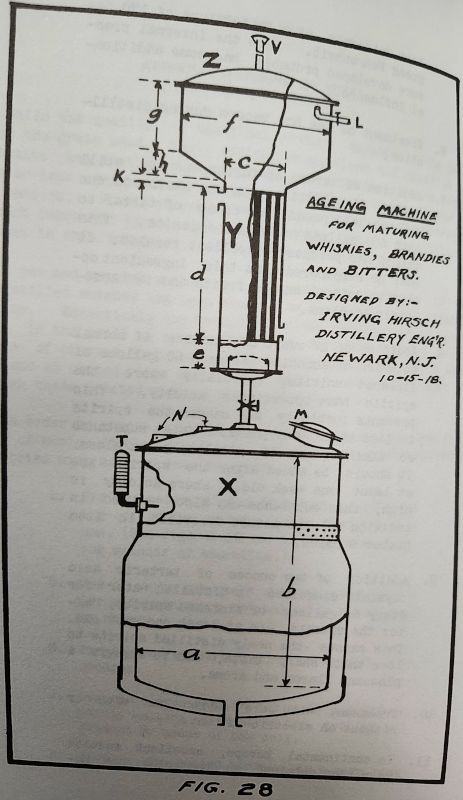

It's their rapid aging idea from 1918, I honestly don't know what kind of effects it would have on a spirit aging wise, but it's basically just a big Fischer esterification still.

DonMateo's Distillery Shed

DonMateo's Distillery ShedThanks mate. Here are a few more fotos. The first is the highly specialised front end loader as still removal crane thingy, the next is yours truly to give an idea of size of this thing and the final is a welding fotos for the equipment guys, which is most of us. The guy with the beer gut hooking up the lifting sling is Raul my gardener. I was going to take a gardners crack foto but that would have been a step too far.

GNS Continuous Still?

GNS Continuous Still?Honestly, I doubt they are really distilling more than 3 times based on the taste. They've already been caught trying to pass their sourced whiskey off as in-house so there's a history of hinky shit.

I guess im surprised the TTB doesn't actually check to make sure...

DonMateo's Distillery ShedWell I finally received my stripping still today. My mate took 58 months to make it. The final boiler is very nice. But dont do what I did. Buy SD gear. Then you wont have to wait 5 years for a peice of gear. Its a 1300l strip with 6 element ports, an 8 " condensor that has 25 copper cooling coils. All local manufacture. I did the design myself one even when I was with my mate bent on bad whiskey.

GNS Continuous Still?

GNS Continuous Still?My main bain marie still is 330l but when i run it with 220l i run it with 3 elements pushing about 6kw each. On a 220l batch it will heat up in about 45 mins and strip in about 2.5 hours. A 330l run will take about an hour and 15 mins depending on the abv and take 3.5 to 4 hours to strip. Again depending on the abv and if it pukes and inhave yo slowndown the first 30 mins.

GNS Continuous Still?@Bolverk said: To run a 55g barrel in 6 hours (using 408w pg ph) you'd only need 3.7kw.

Based on playing around with this design, I can't see how you could do that with such little power.

The latent heat of vaporization of ethanol is 340btu/lb, at 6.8 pounds a gallon for ethanol, we're talking 127,000 BTU's or 37kw total, just to take it from near boiling to vapor. So for a 6 hour run time, you'd need 6.2kw, and that's just vaporization, which doesn't account for heating from ambient to boiling point.

Now sure, you'll recover some energy with the preheater, but there are going to be losses on the piping, column, etc.

I tried to do the math in my head the other day thinking 30-40kw to achieve the 2gpm they state, but it's probably even more than that.

GNS Continuous Still?Ok single pass boiler.

Yeah but who says you have to run it that fast.

To run a 55g barrel in 6 hours (using 408w pg ph) you'd only need 3.7kw.

GNS Continuous Still?Go back and do the math required to heat and vaporize ethanol, and work backwards from your power input to see what that means in terms of feed rate.

I don't have a calculator handy, but I'm guessing you'd be talking somewhere in the ballpark of 40kw to support 2gpm, assuming zero heat recovery (which isn't the case), so maybe closer to 30kw?

That thing isn't a reboiler, it's a single pass 'boiler', in 1 minute, 2 gallons of feed is heated and completely vaporized.

Work with extracts & canning issuesI don't think it's coincidence that so many sprits-RTDs are based on citrus-based cocktails that are naturally high acidity, it's far easier to rely on acidification for stability, especially in the case of a typical sour/sweet cocktail that you can add additional citric to push acidity even further.

I wouldn't want to go the route of pasteurization, it's going to be detrimental to flavor/quality. However, sugar syrups or even granulated sugar are incredibly 'dirty', and third-party syrups should be pasteurized unless you are making it yourself.

The other factor which is a tough one for many distillers, using an aseptic packaging process - tanks, lines, machinery, containers, etc. We're all operating in a sanitary fashion, no doubt, but in the RTD space this is far, far, far more critical, probably more stringent than even brewers need to maintain, especially if products are above the low-3 pH range (think non-citrus cocktails like the old fashioned, rock & rye, Sazerac, Negroni, Manhattan, etc).

Sterile filtration (sub 0.5 micron) is another easy option, and should be applied in-line at packaging time if possible, and will help immensely with maintaining clarity.

Work with extracts & canning issuesI know most of us here make base spirits, but do any of you work with extracts for RTD or NA canning projects? My concerns are for product safety and stability. Any experience/advice would be appreciated. We do bottled cocktails. I keep them 30% ABV or above so I'm not concerned with the safety aspect as much. But RTD and NA projects are a different beast as I can't rely on the alcohol to provide preservative qualities. I can't seem to get around using extracts for stability either. With our bottled cocktails they usually change in appearance after a few weeks - mostly clarification and/or sedimentation via flocculation.

Also, I've read some anecdotal stuff on acidity and sugar stability issues long term (2-3 months). I can't seem to find any articles on the subject that goes into enough detail to understand the issue well enough.

I'm working through understanding safety issues like pasteurization vs preservatives, and consumer acceptance for either one.

Fun fun fun.

[USA/WA] Sale: 5" ProCap 6 Plates 200L KettleStill looking to sell this. Dropping the price to $3000.

No Topic ThreadMorning and merry Xmas to all

Looking for suggestions for future production

For Christmas I made some Limoncello for my brother. It came out really good and is real tasty. The only issue is a black type residue on the surface. Now I understand this to be excessive lemon oils coming out of solution.

When I bottled, I was away and used a basic coffee filter to filter out. Obviously not fine enough and ought possibly have used a depth filter for oils.

In any case, any recommendations for the future.

Cheers.

MERRY XMAS 2023

MERRY XMAS 2023Merry Christmas everyone!

MERRY XMAS 2023

MERRY XMAS 2023Ho Fuckin' ho

Going to hate myself for barreling rum this high

Going to hate myself for barreling rum this highGood point.

Have a number of old ex-finishing barrels that are 53g and larger (60g+ hogshead, etc) that I plan on refilling soon.

Madeira, Cognac, Port, Sherry, etc.

These are all well, well used.

Going to hate myself for barreling rum this highWhy not a bigger barrel to reduce tannin extraction? You can get some seriously old used 53's that would have very little flavor left in them. Or is this one of those look at that barrel and "I have an idea" things... I always fall into that trap.

MERRY XMAS 2023https://www.youtube.com/watch?v=ArSnngsN3Gc

STAY SAFE & HEALTHY | DRINK RESPONSIBLY

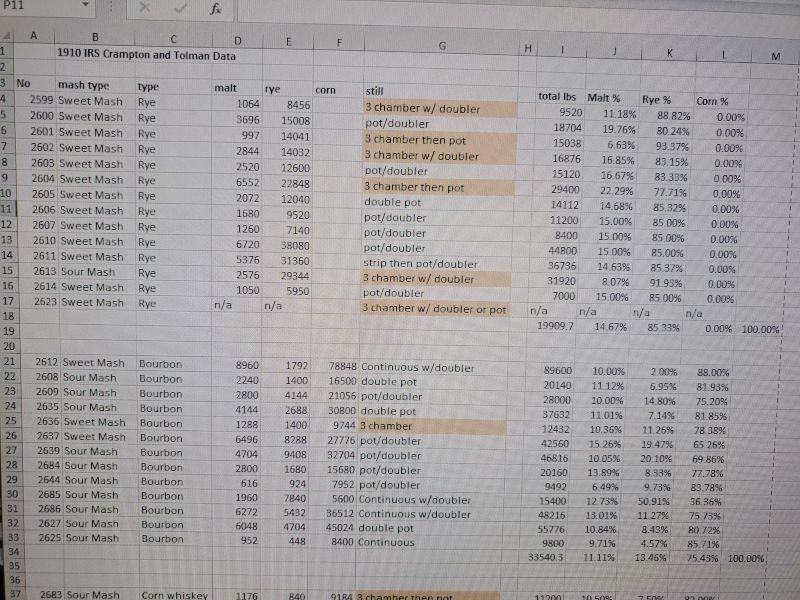

3 Chamber StillHere's there breakdown of who was using what on the Crampton and Tolman paper.

The use of a 3 chamber for ryes isn't nearly as prolific as we thought, just under half of the rye submissions were made on a 3 chamber.

3 Chamber Still

3 Chamber Still@DMdistilling, I don't think I've commented much about the importance of fully condensing the rising low wines vapor vs allowing a measure of vapor and liquid to enter the ,,,well,,,thumper/reboiler?

My feeling is that this is not a make or break detail necessarily. Fully condensing the low wines vapor does mean that you have to potentially install more heat into the reboiler/thumper. Also, to minimize the potential for flooding you'll need a way to drain back to the still. If you are using a thumper to boost proof that is.

This still above is just a stripper and my goal was to fully condense all rising low wines vapor prior to entering the product condenser. Doing so would reduce the flow rate of cooling media exchange. Seems like all the boutique sized operators never have enough cooling capacity.

I am using the coils for the sake of antiquity. On the more recent things I have been working on I am using the through tube design for the preheater and sending everything over as vapor rather than liquid / liquid & vapor.

The preheater coil is a 3" diameter btw.

3 Chamber Still@Smaug since the 3 chamber is an oil extraction machine I would guess the amount of oil in corn could be a concen... it could be too oily? Although maybe it depends on the corn variety?

If you look at the Crampton and Tolman papers 1 of the 13 bourbon participants was making bourbon on a 3 chamber and 2 of the 3 corn whiskey participants were made on a 3 chamber.