-

The Big Gin Thread

Ladies and Gents, I just got a bottle of a gin while passing through London called Gin Mare, that had rosemary, basil and Thyme in it. It was really nice. Not heavy on the Juniper and just some hints of the herbs. I ran a what I thought would be be a copy and it came out really close. The ingredients were Juniper, Coriander, Canela, rosemary basil oregano, thyme, with some Goji berries for a touch of fruit and chamomille for a touch of floral flavours. Very close to the Gin Mare straight out the condensor. On the Basil Oregano thyme and rosemary I only used about 2 grams of each for a 50 l run. The rosemary is the key though as it is fragant and sweet and balances the Juniper well. I only used 12 grams per litre juniper ( per litre of final product) and that seems to me to be the sweet spot for more subtle gins. But I have only done 4 through my fantastic SD gin basket.

Customer Service and First RunThat is why they are your # 1 top notch crew.

Best Craft Rum Wash Mixing-Heating-Cooling Setup currently in use...We are not using the stainless tote yet...

We have a Monday/Thursday program where on each day we ('we' is stretching it, it is my new employee that used to be free intern) empty a 100gal fermenter into the still and start it, clean the fermenter, rack two 3-day old, 50 gallon drums of heated/settled/mixed mix of molasses/water/dunder into the fermenters and add nutrients and 02 and yeast for a 7 day ferment, clean the drums, run the stripping still, mix hot water and molasses in the drums, shut off the still when done and top off the drums with dunder by pumping int though the racking arm to get a whirlpool, covering drums and shutting the lights off... working like clockwork currently and we have a 250gal SD B-M still on order and will look at glycol jacketed fermenters soon...

We have the runs down good enough now we can justify tweaking one thing like yeast culture and have faith that is the only variable...

The Wordless Picture ThreadAnd wouldn't you know, right across the street from Martin Ryan Distilling:

The Wordless Picture Thread

The Wordless Picture ThreadAria Gin from Martin Ryan Distilling - from NGS to gold medal winning gin in every tasting and competition they've entered it in (yes, it is that good)

Portland Dry Gin (traditional English style dry gin).The day we did gin tasting, and gimlets on tap at 10:00AM

Best Craft Rum Wash Mixing-Heating-Cooling Setup currently in use...

Best Craft Rum Wash Mixing-Heating-Cooling Setup currently in use...Greetings to the list,

This forum is great and thanks to all of you here for guidance along the way.

I would add that questions of your target flavor profile and scale are also important.

I am trying to move away from using backset and towards cultivating rum flavor in a mixed ferment. That makes cultivating my whitestar D497 between runs one part of a multi stage ferment.

I take a yeast slurry off the bottom of a running ferment early in the process. This slurry goes through growth stages until I have about a 5L starter from the original mason jar. The new 5L starter goes back to a clean conical to which I add a thin mash of about 10-12 brix. This controlled ferment goes for a couple days and I harvest the yeast again. After I harvest the D497 I then add a 'biome' (essentially a sourdough starter) that can tolerate higher ABV and changes the flavor profile. It's all experimental and I have tried various store bought and wild cultures here with varying success. All that said, yeast cultivation is an important part of searching for my flavor profile.

With regard to scale my processing of molasses looks like this. The Molasses is generally around 80-85 brix when I get it, though I dont have any kind of glucose analysis - just a refractometer that has its problems. I dilute to 40+ brix , raise the pH and heat it up to around 80*C in a mash pot. Future expansion has this mash pot controlled by my kettle controls. It stays at this temp for about an hour, ideally with little to no caramelization. I drop the temp and pH and try various methods to get the organic solids to drop out. I have had reasonable success whirlpooling the thick mash in one of the conical fermenters, where I then store it for a production cycle and dispense for the cultivation of my starters. Essentially decanting the molasses thick mash and taking off the top during the production cycle.

From the conical that holds the thick mash I bring it back to the mash pot, further dilute it to the 10-12 brix, heat process if necessary, chill it and pump it onto the waiting yeast starter in the next conical. I generally will add a little more thin mash to increase my potential abv during the ferment. With one fermenter going I can start the next one. I continue this production cycle until all the fermenters are full or I have run out of thick mash. We are running two 100L conicals and 4 plastic 50L presently, this makes four 100L batches to the kettle.

If I remember correctly, Arroyo recommends a convex bottom for very large fermenters. At this point I don't know about cultivation of top fermenting or pombe yeast. Osmotic pressure in a very large fermenter becomes a stressor.

This system seems to work well at my scale - the stainless conicals are relatively cheap over hear and all i need is a dedicated mash pot and the standard cooling and circulation equipment. And my dream WVO Centrifuge.

Jacketed conicals would be great but I need to learn if massive fermenters change the cultivation game before spending that money. I would imagine you would at least need a different type mason jar.

The Wordless Picture ThreadThough often cloudy and rainy, I did get one brief glimpse of Wy'east (Mt. Hood):

The Wordless Picture Thread

The Wordless Picture Thread

Best Craft Rum Wash Mixing-Heating-Cooling Setup currently in use...

Best Craft Rum Wash Mixing-Heating-Cooling Setup currently in use...Why not strip off some of that excess yeast from your bottom port and go again @grim.

In the brewery we repitch our dry ale yeasts 10 times and "liquid" yeasts we only buy a new pitch every 18 months. Need to be pretty happy with your sanitation alright

The Wordless Picture ThreadSomething I viewed as just a time-filler on the whiskey workshop schedule turned out to be one of the coolest things we did all week. Paul Carlson and Tim Mitchel of Oregon Barrel Works came out to the McMenamin's Edgefield Distillery and showed us how to make a charred whiskey barrel. Paul gave a verbal presentation on the history of beverage vessels, and the anatomy and creation of oak barrels while Tim built the barrel. Two knowledgeable and talented coopers. (It was also rainy and colder than a witch's tit outside the distillery that day)

Tim Mitchel (left) and Paul Carlson

The Wordless Picture Thread

The Wordless Picture Thread

last week ...

No Topic ThreadIn what i am doing which is a 400 Litre LM type still, it is 100% all the time in +100% reflux. i.e. no control. It's function is to nock it all down.

DigiFlow 6700M Connectionone note on the digiflows, they are somewhat limited in the accuracy range...

The 1/4" one (ebay filterdirect "1/4" NPT Digiflow 6710M Digital Flow Meter count up Gallons GPM 56"cable USA" ) is what I use on my 4"x1M condenser using a danfoss valve to keep exit temp at 140F, and it is about right at .5GPM per element (mostly I use 1-3 elements, so .5-1.5 (it says 0.16 to 2.1 GPM, it will kind of start near .07, and good by .16, but near 2 gpm, it restricts a normal pump)

The 1/2" one (ebay filterdirect "1/2" NPT Digiflow Digital Flow Meter count up total Water Gallons GPM 56"cable" I have on my 8" RC controlled by a Johnson/sestos, it doesn't even read half the time, It states "0.4 to 6.6 GPM", but really needs a good .5 to get it going... I need to be able to flow 2+ gpm to flush the air, so I cannot use the 1/4" one.. I may put in a 1/4" with a 1/2" bypass valve for purging air..

I have never calibrated them, it is about 7000 on my 1-10000 priority list...

if you use recirculating cooling water, the slimy buildup can mess with them, I had the 1/4" one blocked for a few weeks, I used city water pressure to free it up...

No Topic ThreadBig ass reflux condensers are very very sensitive to flow changes.

When undersized, sure, you can't efficiently put the column into full reflux, but they are very forgiving.

Oversized, easy to put into 100% reflux, but if you aren't controlling flow rate/temperature impeccably, it's easy to spike the reflux ratio up, and then it takes nearly forever to recover. It's a huge amount of thermal mass.

If you can control the big ass, they are very very efficient.

Foodie - The Food Thread - For Our Food Lovers!Espuma Meanie Gin-Tonic :\">

No Topic Thread

No Topic ThreadAnd the PC

No Topic Thread

No Topic ThreadJust fitting and preparing a RC for welding. Scary amount of welds and just how heavy it is.

Crystal Dragon or Dash?

Crystal Dragon or Dash?Most silicone have a shelf life of 10 years although in use life can be reduced. Chances are though they will not last as long if you routinely take the joints apart. If you fit and forget, use clean in place and otherwise leave them alone, they may last a LONG time.

Making Neutral Spirit from WheyThere's a large dairy company in the west of Ireland that produce something in the order of 10 million L of pure ethanol per annum. I believe they were 1st in the field when it came to whey fermentation. They give away very little, here's all I could I find

fermentation is preceded by ultrafiltration to remove the whey proteins (a useful product in its own right) and reverse osmosis to eliminate much of the water. By this means, the concentration of lactose is increased. After fermentation, a wash of about 3.5% ethanol is obtained which is then distilled to 96% ABV, the maximum achievable in a column still.

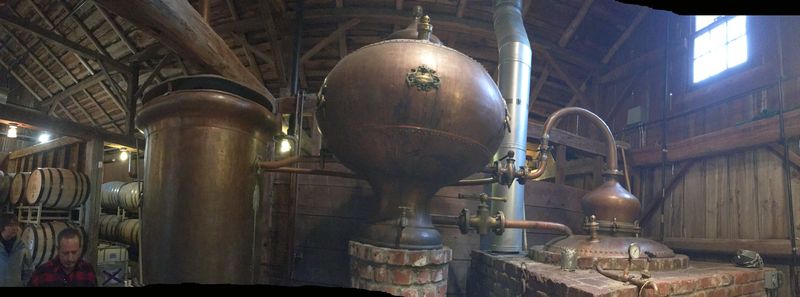

The Wordless Picture ThreadMcMenamin's Cornelius Pass Roadhouse Distillery, Hillsborough, Oregon

Looking out of distiller's barn

Natural gas, direct-fired French brandy alembic used to make whiskey, rum, and pear brandy.

The middle vessel is a heat exchanger, not a thumper. You put the next batch of beer/wine in the heat exchanger and a tube containing vapor from the alembic preheats the beer/wine while vapor is cooled prior to entering the worm condenser. For scale, the top of the heat exchanger is about 12 feet high.

In this photo you can see that the vapor can be valved to bypass the heat exchanger (upper ball valve and pipe going behind heat exchanger) on its way to the worm.

You can also see the well-worn "alarm can".

Ginormous worm condenser

Parrot

Makers mark

Raw materials (unhopped beer is mashed in onsite beer brewery. Wort is transferred to fermentors in the distillery barn)

Pretty barrel heads

Rickhouse (ssshhhhh... sleeping spirits)