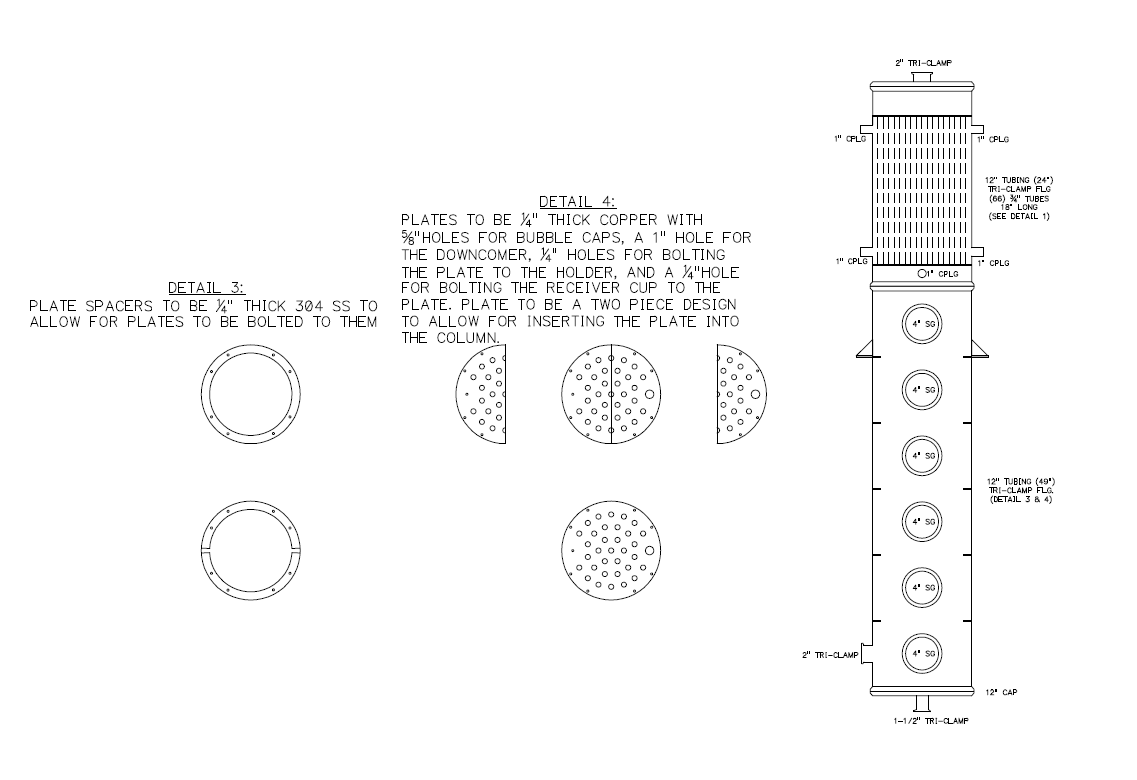

12" Column Plate Design

I'm trying to come up with a design that would allow the use of StillDragon bubble caps in a 12" column. I'm going for a semi-modular design that would allow the plates to be removed if absolutely necessary. Due to the cost of 12" ferrules and clamps, I don't want to put one at every stage. My idea is to use 1" internally welded rings that the plates can bolt to. The problem is; I need a way to insert the plates, so I have come up with two options:

Split the plate into two pieces and insert them from the top. I have measured this and there is room to rotate the plates into place with a plate spacing of 8". I would then use the 4" sight glasses to complete the installation (bolt the plates, screw in the downcomer, etc.)

Keep the plate whole, but increase the plate spacing to 12". Again, I could slide in the plates from the top, but there would have to be a gap in the holder ring.

I like option 1, but my concern is that the gap in the plate could decrease performance, but I guess it could also act as a "weep-hole" to allow for full draining of the plate.

A picture is worth a thousand words:

Also feel free to leave feedback on other aspects of this design.

Comments

Black Coral Rum uses a plate tree for his column.

His 12" SS pipe was not at all round (made in USA haha,,,,,,,ha), so he did a very good job of honing the interior by hand. Then to further prevent weeping he constructed a retainer (wall?) around the circumference of the plate at about the same height or perhaps just a bit more than his established liquid level elevation. He did a great job of getting the tolerances to a minimum. In fact you can hear the suction forcing through the plate assemblies when he slides the tree into the column.

He (Black Coral) seems content with this design.

He extracts his entire plate tree as one unit after each run and douches to clean the copper. He dunks the entire plate tree into a commensurately sized vessel to clean. He uses blackstrap and his runs last about 28 hrs. I've not seen his bottom plates but I can imagine they look just lovely after a 28 hr run of blackstrap beer?

He cut his own plates from sheet that he sourced and populated with StillDragon bubble caps. He constructed his own downcomer solution.

I tried to talk him into provoking @Lloyd into building larger caps but he has his still dialed in pretty good now and is very happy with our standard bubble cap.

I have to say that his rum is simply unbelievable.

Sorry for rambling.

StillDragon North America - Your StillDragon® Distributor for North America

No. That was a great ramble. Thanks for the info.

So it sounds like he got a pretty snug fit then. So is a "tree" design where the plates are supported from the plate below it (like with threaded rods or something)? That's a pretty smart design and it requires less welding.

Do you think if he added some weep holes to his down comers that he could clean in place ? Or is it just too sticky?

+1 on @Smaug's post

I've only seen the plates supported by a central rod (threaded), and held with bolts above & below each plate.

You can liken the rum deposit to a dinner plate. Which has had spaghetti sauce left on it, and sat out in the sun for a few days ~X(

Yeah, The rum beer can get pretty nasty.

In Black Corals case, a simple hose out will not even touch the greasy build up. He feels compelled to douche his plate tree unit after every run.

StillDragon North America - Your StillDragon® Distributor for North America

Is the rum residue really that bad? I haven't run a plate column yet (I'm ordering one next month), but when I run a pot still it seems like I get a lot of residue in the kettle, but the column stays relatively clean. I guess I'll see next month...

I'm trying to stay away from removing the plates after every run. I feel like it would be a time consuming process to remove the dephlegmator, extract the plates, clean them, then reassemble everything. Rum will not be my main product, but I plan on running it every once in a while. Would other products (Gin/Bourbon) require such stringent cleaning?

If there's no way around it. So be it. But a clean-in-place (or soak-in-place) option would really be beneficial.

I guess back to my original question. Does having vapor paths (besides bubble caps) between stages significantly decrease performance? If I could have "gaps" small enough to allow for good performance, yet large enough to allow for spraying, soaking, and draining all the plates I feel like that could be the best of both worlds. And then I could occasionally extract all the plates for intense cleaning when required. Thoughts.