Welcome!

Be part of our community & join our international next generation forum now!

Categories

In this Discussion

- CothermanDistilling March 2017

- crozdog March 2017

- fadge March 2017

- Fiji_Spirits March 2017

- grim March 2017

- Mickiboi March 2017

- punkin March 2017

- richard March 2017

- Unsensibel March 2017

Safety and Ground Connections on the Element Guard Kit

Hi all,

I've been out of touch for a while with work, life and everything else in between.

Today I thought perhaps I might post a few pics about a little problem I had recently, just to ensure our new members and perhaps a few older ones may read and take notice about the electrical safety issues we face in this hobby and the possible outcomes including burn outs, fires or even death!

Just in case I'm in AU and we have 240v with standard wiring at 10 amps, some of us are lucky enough to have 3 phase with up to 60-80 amps, in these pic's I was using the 2 legs of a 3 phase with 15 amp leads, sockets and switches, all running with 3600w elements (15amp) with and without a controller.

USE GROUND AND CIRCUIT BREAKERS

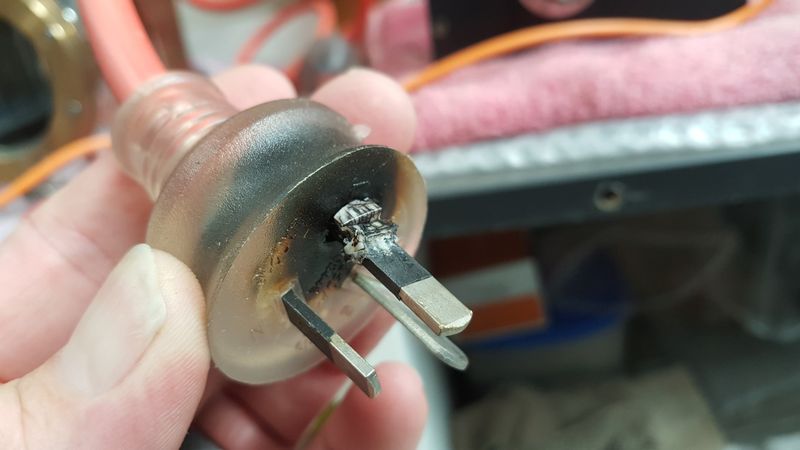

The problem, hot, overheated and almost melting ....

The cause..

One leaking element + power + 3 concurrent stripping runs and the breaker did not trip before I noticed something not quite right, felt the lead and it was "hot" yanked the lead out while dropping the electrical board main switch to off and ready to grab one of the two fire extinguishers I keep right near the still and mains board. Got lucky with this one, as I had been touching the boiler and column during heat out and throughout the run.

Notice the rust on one leg of the element and the inside of the element, note: no liquid was seen "leaking" from the weep hole in the guard seal its at least 5mm gap.

Both my elements have a ground connected, next job is to ensure a RCD is working and not bypassed or wired incorrectly. Not in a rush to run again until all checked and I have replaced all power points, leads and plugs.

Be safe

fadge

Comments

lucky mate.

I have several small breweries near me, many electric... every one had issues like this, and it can be avoided by treating the electrical connectors like lug nuts on a trailer wheel... check for tightness on a regular basis....

and it can happen in your kitchen too:

Correct .... check for tightness of all screws.

You have a single phase 240VAC supply ..... same as us in SA. Generally we have our plugs with 2.5mm2 wire and 20A breakers.

Something else looks wrong and my gut feel is a toasted element that has caused this problem.

G'day Fadge, lucky mate. Do you think it is an issue with the elements material, design or seal? Is there anything i can get the factory to improve in your opinion or improve on our EGK design?

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

@punkin

I have looked at the element and it seems that it leaked at the point between the stainless backing and the pass through for the connector. I had lugs on the wires, plus shrink wrap on each with some tape for good measure, as when assembling the EGK there can be a little bit of excess wiring that gets pushed in when doing the outside clamp/plate. Also it could perhaps be when screwing the element in, i only ever use my hands, no tools to tighten, the seal is tight. The element seal appears perfect with no sign of leaking anywhere

Lucky I have a spare, and this one better not leak, could not be that unlucky.

Anyway no harm done, no fire, no shock, just some lost time and a few expenses for repairs and replacements.

Now that's what I call a very good day.

Fadge

I'll send you a replacement mate and get you to send it back to me and i will return it to the factory for an explanation if that is the case.

What wattage is it?

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

I have never checked mine. After seeing this it's on the first thing to do list before next stripping test.

I have feedback from the factory. They said they have never had this reported from the thousands of this style element they have produced. But they are also saying they will argon flouride weld the terminal side as they have but also braze the immersion side.

I'm positive the suspenders and braces approach will prevent a recurrence.

@fadge please either send me a PM or email with the wattage and address and i'll send a replacement and satchel for return of the faulty one.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

Years back didn't we talk about filling the element guard with potting compound after it was assembled?

Yes, I know this means that if van element goes bad, the guard kit becomes disposable too.

As a matter of course I put a thick piece of wire insulation down inside the element adaptor so that it won't allow leakage into the walls of the adaptor. It's a tight fit and that heat shrink ain't enough by itself IMO. That has helped a great deal by itself.

I also ran a ground rod for the elements and still and added RCD/GFI breakers on everything.

Honestly tho, the little piece of scrap plastic wire insulation around the connectors made most of the difference.

@grim actually not a bad idea. From my observation in reality, for a hobby scale, how often will the element go bad? On a commercial scale, same question? I think @CothermanDistilling reported already running for 2+ years on the first set of elements

yep... I have not burned out an element since I upgraded from a water heater years and years ago, and those were the copper elements... hey, I was a noob, and the 'dash' was the new replacement for the torpedo... and Larry had those copper funnels in stock... still kick myself for not buying some...

Something else to possibly consider ...... Depending on the damage, you may have to change your 3 core cable. On my kettle heating I used a 6mm2 3 core cable. for the 5.5kW element.

I will note my system was run a fair bit with 2 x 3600w elements for around 3 years until one element failed. Replaced and only a few runs before this hiccup.

15amp leads, heat shrinked on the element connections, electrical, but not a watertight seal, then electical tape as well.

New leads and new power points then a new spare element and good to go again, just a few dollars spent to have peace of mind, reckon I will watching the process a lot closer on the next few runs however.

fadge

New element left today with a satchel to return the old one mate.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand