Welcome!

Be part of our community & join our international next generation forum now!

Categories

In this Discussion

- CothermanDistilling May 2014

- cunnyfunt May 2014

- irishman May 2014

- jbierling May 2014

- jonno May 2014

- Law_Of_Ohms May 2014

- Lloyd November 2014

- Moonshine May 2014

- punkin May 2014

- SDeurope May 2014

- Smaug May 2014

- Sunshine May 2014

- TheMechWarrior November 2014

TC Flex Pipe

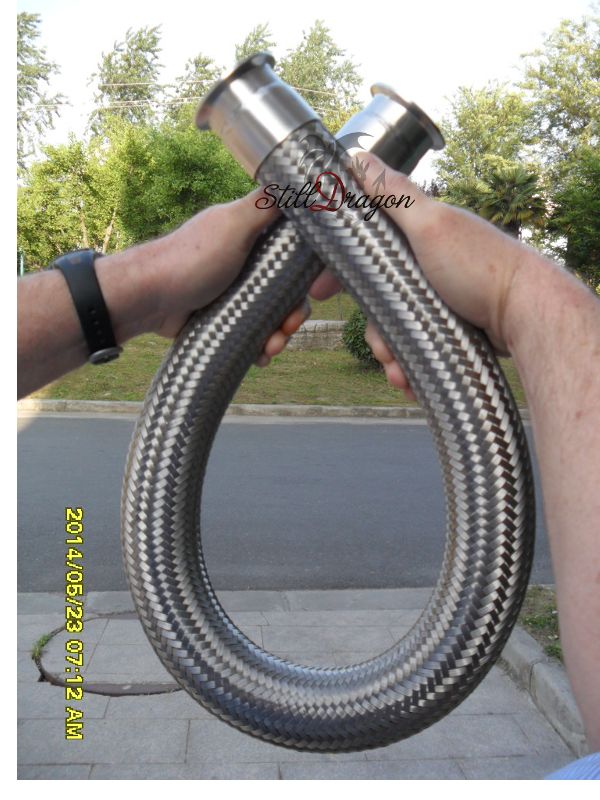

Got my first samples late last evening of TC flex pipe.

It can be made in many different sizes and configurations - flex pipe only, pipe with outer braiding, pipe with insulation, etc...

The braided pipe looks great and the insulated looks a little cheesy, just insulated plastic tube slipped over and hose clamps to keep it in place. I'm sure it would do OK but it cost the same as the nice braided hose and doesn't look as professional.

Its flexible enough but it won't make a sharp turn.

I'll discuss this with the factory but I'm going to assume this is "just the way it is"...

weld burn on the inside and for some folks that's a big turn off.

And on my new table mount condenser where I need to cobble together different size TC pipes whenever a configuration change is made:

Comments

That's kind of awesome. The flex pipe really lends itself to modular.

StillDragon North America - Your StillDragon® Distributor for North America

Wow!!!

Excellent. Looks great mate.

It would be great if we could get the inside polished out where the welds are though. As you say, many people will not like it.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

I figure that's the reason we haven't seen it available before @punkin. We crack that nut we could be golden.

Gonna complain enough to get then to try to fix it :)

+1 AWESOME!

StillDragon Europe - Your StillDragon® Distributor for Europe & the surrounding area

Going to give them another chance so ordered another sample.

How small a size are you able to get these in @Lloyd?

Don't know but surely 3/4" TC should be available. I'll check when they3/4" TC is not a problem.

Wow! The question is for me, is it easy to clean (to prevent flavors to sit in it)?

StillDragon Europe - Your StillDragon® Distributor for Europe & the surrounding area

I don't know but they say they supply these mostly to beer companies. I bet if stuff was left inside for a long time that it would be hard to clean.

It's what I'm thinking, using them as beer lines in a herms setup

Oh, they apologized for the shoddy looking insulation layer, saying they used it because they didn't want to buy a whole roll of the 'right stuff' for a sample. =))

I pointed out that the sample is the difference in getting our order or not and we couldn't order with samples like these.

Anyway, they (actually she) says that hot beer is almost always used with the braided layer and not the insulation layer. Haven't run it yet but curious to see how hot the braided outer layer gets on my still. I'm thinking hot, but might be surprised.

Braided looks way better.

Your Place to be >>> www.StillDragon.org <<< Home of the StillDragon® Community Forum

It's hard to tell from here, but what is the inside surface like? Is it a smooth surface? The 3rd picture isn't showing up for me. If it's sanitary, i'd be interested in some various lengths of that...but mostly for the beer end of things.

Sorry for that, the problem is fixed now (I've watermarked @Lloyd's pics so that no-one forgets whom they have stolen that idea from ;)) ).

Your Place to be >>> www.StillDragon.org <<< Home of the StillDragon® Community Forum

I wonder if "pickling the weld" can be translated in chinese

https://www.youtube.com/watch?v=ty6eY9VUIgI

Technical blah blah..

https://www.youtube.com/watch?v=ty6eY9VUIgI

Looks like they did OK on the next sample. Cleaned by hand and they are saying they want me to buy big (whatever that means) so they can buy a machine to polish it.

Last of my concerns gone. Looks like a goer. Definitely the braided one and i'm guessing we'll need it in 2" 3" and 4". Probably in short and long, say 300mm and 600mm or even 900mm. What length is your sample?

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

My sample was 1 meter long. I just ordered another (they sent the picture that you see above) of 2" x 0.5 meter. Not sure why we'd need 3" or 4" but 3/4" might be useful.

Because the take off of the stills are in 3" for the 5" and ^" and 4" for 4" condensors. You'd run one of these between the reducer above the reflux condensor and the product condensor instead of a 180.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

Well, that makes all kind of sense @punkin. Especially if the product condenser is wall mounted or table mounted.

Table mounted mine recently and just love it. No need to drain and unhook everything for a configuration change and the table is so convenient for changing the collection bottles.

Nice. I'd be interested in .75", 1.5", 2" and 3".

Niiiccccce!

those first welds look like mine, so I don't feel so bad now!

.75" for product condenser to show fire marshal that is it a closed system (hoping they do not notice the holes in the surge breaker ;-)

2" - great for putting the column(s) or pro gin basket beside the still

3,4", great for u-bend replacement

overall, could be used for bends, but really best just to give the little bit of flex in a straight section, and best used vertically to reduce smearing..

I agree. It beats trying to cobble together a collection of TC pipes. The need became apparent when I table mounted the product condenser.

Stripping still?

"special" machine to polish it? like?

..

https://www.youtube.com/watch?v=ty6eY9VUIgI

But in all serious, 3/4in pipe for the water connections to the deflag and shotgun would pimp my ride!

https://www.youtube.com/watch?v=ty6eY9VUIgI

swagelok is not pimp enough?

Not when one is thee pimp.

StillDragon North America - Your StillDragon® Distributor for North America

Any progress on these sexy TC braided lines?