Welcome!

Be part of our community & join our international next generation forum now!

Categories

In this Discussion

Help with 1000L Still

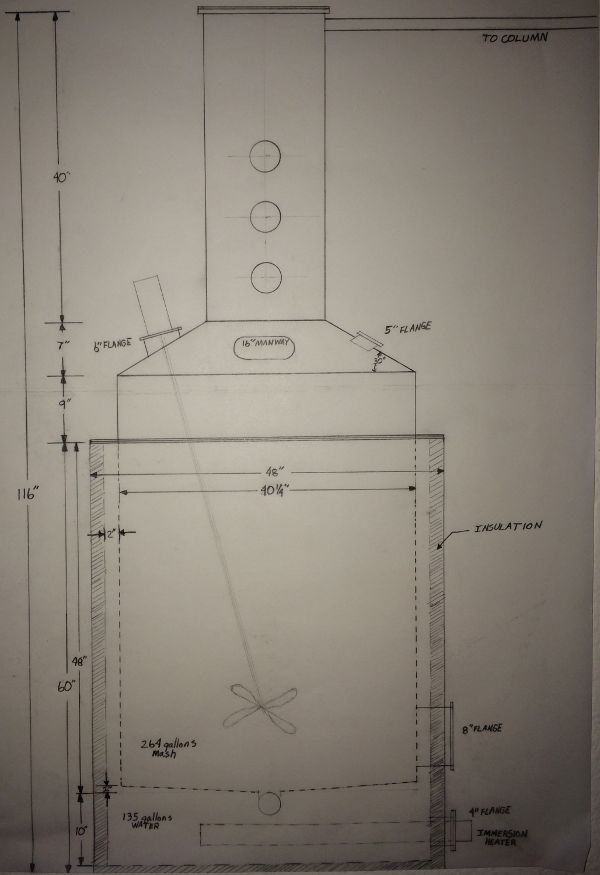

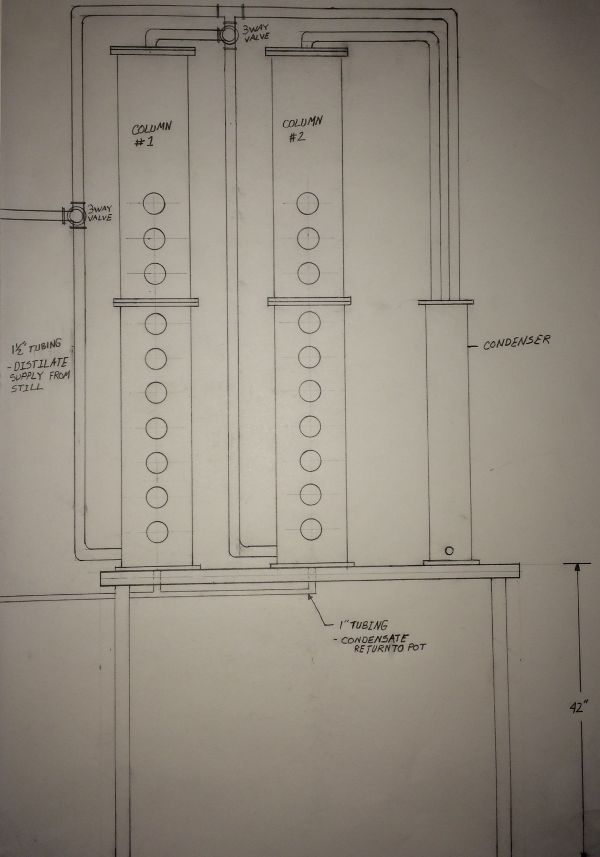

I am in the process of building a 1000l steam heated still. I have been trying to model it off kothes vodka model. I have run into a few road blocks with the plate design and wants to see if I could get some better ideas from you guys. This is my first attempt at building a still at this scale and I feel I am in a little over my head after reading some posts on here. So, you could consider me a novice.

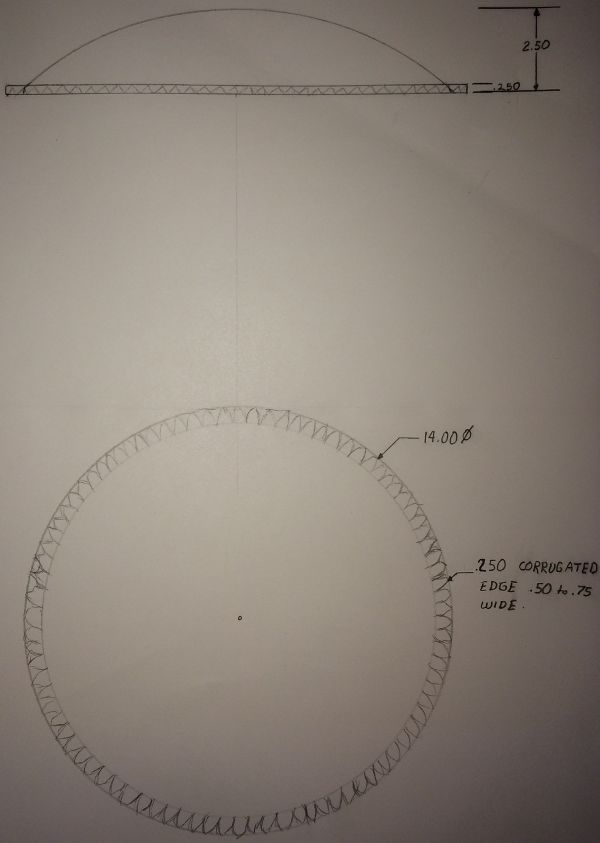

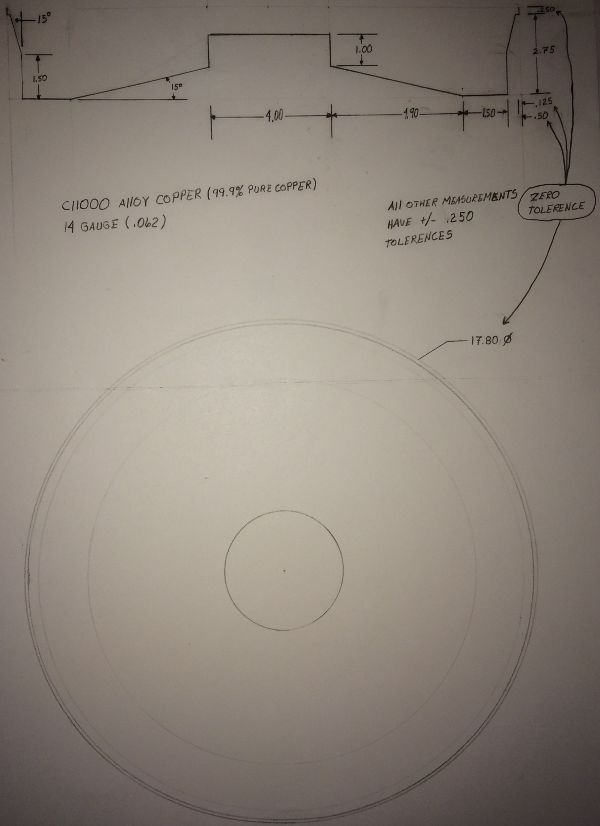

I found a couple machine shops that do metal spinning, thinking I could have these trays and caps spun. Well they came back will prices from $12k-$20k for 18 trays and caps.

I have nothing put together yet, I have just been getting all my pieces together the last few months. Sight glasses, thermometers, thermowells fittings ect.. I designed the two columns to be 19" in diameter and in 4' tall sections. The top of each column would have its own deflagmator. I wanted to have a set of beadings rolled into the columns to hold the trays. I didn't want to weld the trays into the column I wanted to just snap into the beads.

I need to figure out a cost effective alternative to these trays. I would be open to any ideas. Even if it meant redesigning everything. I'm still at the point to where I can do this.

These drawings are my first design, a waterbath electric heated model. I have sense changed it to steam. Just haven't gotten the drawings done yet.

If I could get some input I would greatly appreciate it.

Cody

Comments

Hi @kodered22, I'm Lloyd - one of the Dragons of StillDragon.

Your need is understood and since no-one else has answered I'll chime in.

First of all we are fully modular. We design and produce parts that can be fitted together to create amazing things and fulfill crazy ambitions and desires. Like Legos but for big boys.

Your plan is not modular so no has answered your request yet here. Not saying that it's wrong but just saying it might best be served on a different platform/forum where stuff is welded and soldered together permanently instead of more moveable, adaptable and fluid.

Also we have not graduated to 19" column size yet. Or even 12" yet. We hope to get there someday soon and 12" is definitely on our plate of things to do.

Please look our forum over and see if you can help us as much as we can help you.

Your very first post to our forum was not an introduction but a call for help for something we are working toward in the future. We are at 8" size right now, not 19. 12" is in our cross hairs.

Your plate design was shown by a guy in Sweden that has now gone his own way and it makes little since to me except by mass producing many to save costs and lowering the price. (Read: $$$$ spent for the custom molds to produce affordable plates).

But that can not be done without a complete explanation of why. Just because the million dollar still manufacturer is making the giant plates is not an enticement. Again, we are not at 19" level but at 4", 5", 6" we rock. Probably at 8" we rock too, gonna rock even harder soon as new SD tech is unleashed.

19" is untested in this plate design .... by you too, right? Or is it a propitiatory design that you want to emulate from a million dollar still without paying them for it?

Just saying, you want 8" columns or smaller then this is the right place to be until we get bigger. Even then, I'm not sure that the plate you describe is in our modular future. But I never rule anything out until it is proven anti-modular.

Glad you are here and hope you can contribute more @kodered22.

Two cents from the peanut gallery. Disclaimer - I know nothing about anything. Assume everything below is false, worse, a lie.

Why a 19" column? While not oversized for a 1000l, it's a serious amount of metal. You could likely scale back to a 12" column, and the only tradeoff will be a little bit of speed, but likely at a huge discount. Is the cost the main factor here?

Not that I'm selling for other manufacturers, but at $20k for caps and trays alone - you'd be better off talking with the commercial guys who are having components built in China to their spec. Perhaps they would be interested in supplying you with the column alone, and you could fabricate the rest.

Are you sold on the single large cap? To go modular, why not find a shop that can cnc drill copper sheet. Have each tray made, calculate the appropriate number of SD bubblecaps and downcomers. I bet you that you could do trays with SD caps for less than half the cost, no spinning needed. Probably even less than that if you can drill out the plates yourself. Now, you'd probably have something like 75 caps per tray, and at 19 trays would probably send Lloyd screaming (~1400 caps).

Also, have you followed the Red Door thread? He's getting very good speeds using perf plates and an 8" column, at significantly less cost than the proposed approach.

To prove out the design, you can start with the plates on the main still first, prior to making the investment into the second pair of columns. Even at 12", I suspect you'd have no problem with the speed of this approach, given you have enough steam to push this thing. Heck, since I'm just making up numbers at this point, I'm sure you'd be able to push through 30l/hr, and probably have a run complete in 5 hrs, give or take.

Good luck, very excited to see pictures, this would rank among the most ambitious self-builds I've ever seen (if not the top).

(Or, just start with SD gear, and make enough money to afford the $200k Kothe or Carl outright!)

I think the above two responses are spot on... save them for future requests of a similar nature... additionally, @grim has nailed my plan in his last sentence....

It's our plan as well, nice to see some confirmation. I know we aren't SD's market, but we'll drag Lloyd and Larry along screaming.

I saw the posting on here of the Swedish guy making a still similar to kothes design. This is why I thought this would be the right place to take my questions.

I'm actually starting a new distillery in Michigan and this still will be a focal point of the distillery. I wanted something impressive to look at, I don't think an 8" or 12" column would be as impressive in a distillery. Another reason why I wanted to go with the 19" is because it's really not that much more to do it compared to a 12" diameter. I am buying my copper in 4x10' sheets and a sheet cut in half, at 60", will give me a 19" diameter column. A 12" column is almost 37" and I can get 3 out of each sheet but I still am buying two sheets for the two column walls. I run into the same situation with the trays. I can only get a good price on the copper if I only buy them in full sheets. It's about 40% more in copper but I'm buying almost the same amount of copper to do the job. The larger size really just means a little more copper and that's peanuts compared to the rest of the cost in components and labor to build it.

I wasn't necessarily looking for help with the Kothe caps. I am looking for an alternative to those caps. Something that will work as efficiently as possible and not cost me $20k (like the Kothe caps and trays). I am not sure how to design a standard bubble cap and plate. I have read a few posts on this forum that, sort of, go into the design (this is another reason why I felt I was safe asking my questions on here). I'm not sure about the spacing of trays and caps. The size the caps need to be. How wide or tall the slots need to be. Vapor pressure Sizing difference in caps from the top to the bottom of the column. More so theory questions.

I'm sorry if I wasn't very clean with my intent with my first posting.

I would be willing to work with you to develop a 12" Crystal Dragon (or SS Tees).

What could be more impressive than that? You and I can have a really big party with the left-over of the $20K.

Clamps are still an option in 12" but bolt flanges would probably be better.

We can go as large as 400mm (about 15.75") with stock size (non-custom made) glass and custom machined bolt flanges (forget clamps at this size). Bolt flanges can be machined in ANY size.

It will take about six months for you to get it by sea freight if we started to develop it together right now. A month to figure it out, 2 months to produce it as the custom gasket molds would need to be made, a month or two for the sea freight and 2 more months because nothing goes according to schedule.

Please, please move forward with the 12" diameter.

StillDragon North America - Your StillDragon® Distributor for North America

We may be willing to work with you on this project, the timelines aren't ideal, but the end result will certainly incredibly impressive.

After visiting more than a dozen distilleries over the past few months I've come to the realization that the public really doesn't share the same kind of still-porn addiction as we do, and that is OK. Yes, they tend to be very pretty, but honestly, most lay-folks would be just as interested to watch an open fermenter bubble angrily.

But being able to see spirits dance in a glass still of that size? I think that would be a real treat for a visitor. Looking through peep hole sight glasses wouldn't ever be the same.

I find people are incredibly impressed at the SD dash, even more so than the crystal dragon if they are not in use at the time...... but once they are operating, the CD is where it is at... most people don't care copper or stainless, just that it is shiny...

Side note, the insulating effect of the glass is a huge benefit to those of us in a warmer climate...

How do you keep your sulfur compounds out of you distillate? The boilers I have seen on SD are all stainless and the columns are all stainless or glass (with the exception of the trays). If your making a whiskey and want to bypass the column, the distillate won't have any contact with copper. Do you have any sulfur compounds coming threw in the neutral spirits?

How many 12" column sections would you have to stack to reach azeotrope? This would also be my production still so I don't want to spend all day on one batch. I was looking for a design that would take 5hrs to distill one batch. I want to be able to get two batches in a day.

How much would one complete column section cost?

copper plates is enough, even making whiskey it is recommended to still use a few plates(2-4).

What level of sulfites do you have in your wash? Have you measured it? there are previous discussions on this forum and countless on other forums... bottom line for this forum is that there are other methods for craft distilleries to get rid of sulfites, but there is potential liability in just publishing the information as it is potentially dangerous if not done right... some CD operators use stainless perf plates... no copper...

The number of plates to reach azeotrope is dependant upon still charge strenght and the speed you want to run... you could do it with 4 plates and a 6-8% wash charge if you want to go really, really slow, or with 8-16 plates and a 40% low wines charge if you wanted to do a production capable rate... also, the Reflux condenser or dephlegmator is essentially a variable plate and can be used to fine tune the rate so that you are not only getting Azeotrope, but the flavor you want... (you can still have some flavor at azeotrope if you still is designed and operated correctly...)

The 12 inch CD is a top plan. If you are after a stunning visual still then that,s as good as it gets. The new plate system should be revealed in the next few weeks and that will revolutionize not just your design, but the whole industry.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

So it begins today.

We will order a 12" sight tower and a 12" Bubble Tee into existence today. Maybe 2 weeks to get.

That will give us all the measurements that we need to design the plates as they must be compatible with both CD and Bubble Tees.

Since its 12" I'll have a 6" sight glass union installed on the tee. It will add a little height to the tee but I've asked for the tee to be as short as possible.

Let's not think about the dephlegmator just yet but stay focused on the column under it.

I won't know costs for awhile but I'm very confident the 12" Tees come with some sticker shock. All 12" TriClamp stuff is expensive. The CD won't hurt nearly as much.

12" boilers?

12" diameter column.

Should just stick with CD for the 12in and above,

https://www.youtube.com/watch?v=ty6eY9VUIgI

Above 12" we can't use clamps. Its all bolt flange stuff from there.

I ordered a very expensive 12" clamped sight tower today but starting to think it may have been better with bolt flange ends. We'll see.

All SD boilers made to date have ferrule column ports so that would be yet another layer of adapters - clamp to bolt flange.

I read a publication on the interactions between silicone and ethanol, although it was a small amount, it was saying there were toxins released when a high temp ethanol came in contact with the silicone.

Have you guys did any research on this? Have you experienced any off flavors?

_How do you keep your sulfur compounds out of you distillate? _

Primarily by controlling fermentation, but also good yeast husbandry and mashing technique. Spirits are made in the mash tank and fermenter, not in the still. I don't care how expensive or shiny the still is, it won't take a bad wash and make a good drink (except in the cases where a baaaad wash is specifically what you need to make a good drink).

Under pitch into high temperatures, don't control fermentation temperature, stress the yeast, wrong amounts of the wrong nutrients ... you'll have sulfur compounds.

Pitch cool, control temperature, use the right yeast and keep it happy, don't rush the ferment, and like magic, little to no sulfur.

Run your wash through a stainless still, does it smell? If so, don't blame the still, blame the cook. I'm sure I'll take plenty of heat for saying this, but it's true. Copper hides many ills, impatience being the main one.

The copper plates and caps alone should provide more than sufficient contact to reduce any residual sulfur compounds.

@grim: The University of Hohenheim Germany came to the same conclusion. Only very small amounts of copper are needed for distilling. The fairytale of copper stills is still kept alive because copper is cheaper than stainless steel and the big distilling firms want to make a big profit by selling their stuff. It is much more important to have a good control of fermentation.

StillDragon Europe - Your StillDragon® Distributor for Europe & the surrounding area

Could you post a link to the information please?

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

It's a tough read.....

http://www.foodbase.org.uk/admintools/reportdocuments/256-1-465_Silicones_Final_Report_04_03_05.pdf

@sunshine Since when has copper been cheaper than stainless steel

https://www.youtube.com/watch?v=ty6eY9VUIgI

page 159 graph appears to release (probably residue?) and then tapers off over time to almost undetectable levels - similar to the CO2 beverage test or the orange juice test. Appears to be a "cleaning run" where the nasties get washed away.

It IS a tough read.

Lloyd

The time in that graph represents the time during the MS separation run. All samples in the study were exposed only once to a food simulate for 4 hrs (95% EtOH). It would have been a more powerful study to do repeated exposure to the same silicon sample to see if extraction went down after repeated exposure but that was not done. The report does suggests that hot EtOH does extract significant amounts of silicon components from the sample which is a little disconcerting to me.

FYI, I read these types of documents on a daily basis.

You are correct, a repeat of the experiment after the cleaning run would very probably have resulted in a very different dataset.

MORE importantly is the amount of contamination carried over to the distillate - through the dephlegmator and past the product condenser - vs returned to the boiler to be flushed away with the stillage. That was certainly never addressed or tested.

The silicone exposure is minimal in a Dash or CD, vs the exposure in the experiment where it was so weighted the opposite way.

But to each his own I say. Stay safe and do as your heart and brain commands.

I also was like you not so many years ago and anything "plastic" (silicone included) was taboo. I have since learned that all of that fear is bullshit. There is simply too little hard science that can disprove silicone gaskets.

Teflon was also taboo for a long time (see HD forum) and that was debunked. Now they have a hard time justifying their anti-everyting stance.

Again, its up to you and your sensibilities to best determine what is right for you.

I have no problem with silicone gaskets and I respect your right to differ.

@LoO not the material, it's the labor that makes copper for the usual suspects cheaper. This is what the former senior sales manager of Carl told us, when we asked the same question.

StillDragon Europe - Your StillDragon® Distributor for Europe & the surrounding area

Everything leaches something, including metals, especially copper. And we all know copper is especially toxic. Spirits contain plenty of trace metals.

Liquids are more than happy to dissolve surface contaminates. While you make think your surfaces, piping, and hosing are clean, there are plenty of trace compounds just waiting to be dissolved in your liquid. Caustic? Cleaning fluids? Even dissolved water residues.

Filter plates… yep.

Barrels? You don't want to know what kinds of nasty things are extracted from the wood. This whole process is based on leaching things out.

Even fermentation produces carcinogenic by-products, the best known in ethyl carbamate, which require the presence of copper to form. So if you use a copper condenser, parrot, etc - you'll increase ethyl carbamate production and add known carcinogens to your product, as well as toxic copper to your spirit. (copper early = good, copper late = bad)

Even the "gold-standard" teflon has been implicated in conspiracies (see Lloyd above).

I won't even get into the fact that many using feed grade grains don't even realize that those grains had been treated with all manner of fertilizers, fungicides and pesticides.

Sure does taste good though.

don't forget the plastic containers for the mash. Used 100 times, the inside is showing signs of abrasion and even food grade plastic is said not to be safe, when it's ageing.

StillDragon Europe - Your StillDragon® Distributor for Europe & the surrounding area