Welcome!

Be part of our community & join our international next generation forum now!

Categories

In this Discussion

Hello all

Hello all just joined the forum pick up some new gear from @punkin. It arrived the other day and I thought I should put it together tonight. Very happy with it @punkin. Dry humped it a few times now its tucked in to bed. Some people will know me from other forums I look forward to reading and chatting to every one in the forum.

Thanks

stilldragon.jpg

479 x 800 - 52K

Comments

Dry humped! I pre hump everything that goes out for good measure.

Early on I have to admit that I almost didn't want to send out parts because they are so beautiful compared to any thing that was available in stainless. I wanted to keep it all.

Welcome and use your equipment in good health.

StillDragon North America - Your StillDragon® Distributor for North America

Damn, a three inch product condenser? Welcome aboard!

Looks great mate. Hopefully those extra downcomers will be here next week.

It looks a beast with the big PC

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

Well I have yet to use the new still and its not by choice work keeps getting in the way of getting it set up. Still got few things to pick up like pipe fittings and so on befor i can plum it up for water and give it a good run.

But thats not what this post is about.

I have just put down a depoit on a 120lt boiler through punkin. Was wondering if any one got pictures of the legs and feet of em as I want to work out how i can put it on wheels and make it adjustable so i can make it level.

Ran my pot still on the weekend strip some rum wash looks like it might tern out to be a ok wash.

PS was not shaw where to post this so I thought I would just keep using this old post of mine. Thanks Drunkas

http://www.stilldragon.com.au/

Not a great picture, still trying to get set up after the move.

The feet already are adjustable. Are you sure you want casters on your boiler? I'd rather mine not move around.

Thanks Lloyd for the pics. Yes I do. I need wheels as I dont realy have a spot where I can keep it set up to run all the time. Not untill I extend the back of the shed by 10x30ft and that projec wont start till mid winter.

http://www.stilldragon.com.au/

It's really too heavy to turn over by myself since the column is still attached but it appears to have 1.25 or maybe 1.5" FPT that your casters could screw into.

They are a pretty big thread, you can just see the thread on one of the feet at the back in one of Lloyds photos. Let me know if you need more closer shots and i will get some shots.

The other question i need answered is what height people want their boilers. I'll put a post up in the other thread..

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

Thought it was about time I did a cleaning run for the first time since I picked this up from punkin

First time any thing with it.

https://www.youtube.com/watch?v=LjVT34wx0Z8

http://www.stilldragon.com.au/

@Drunkas, those are some crazy videos you have on your YouTube account. I swear, watching VIDEO0030 was like driving that thing myself. =D>

Your Place to be >>> www.StillDragon.org <<< Home of the StillDragon® Community Forum

Looks excellent mate. That 3" shotty is a very nice addition, you'll be able to dial the water right back to that in the winter.

Amazing how little water it took to knock actual steam back to full reflux too, how much power were you running there?

Top looking unit. ^:)^

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

@punkin I was running on gas hard to say how much heat/power I was using. My gas burner is made from a yard gas heater like this one. I was running it on about half.

I need to make few changes for safty as my parrot is right above the heater. I got 50lt of stripped rum was probly at about 50% abv Im tempted to throw that in and see if I can get the take off set to 65%abv. I like my rum at 65% for aging. I also got a bunch of failed experiments saved up in a keg so will try a neuteral as well. At this point I will not be doing to much with it as I got it for making grain vodka and that wont start till next grain season. I live in the weat belt in SA. So I plan on playing around with it next season.

@Moonshine I got lots of old stuff from the old days when they made things to last. I should make a thread so we can post all the old stuff we have collected.

http://www.stilldragon.com.au/

I gave her a good run last nigh. I loaded my boiler up with all my failed spirit recipe attempts. I manage to dial it down to 94.5 prity quick. I took 5 lt off at 94.5 then I sped things up to 93 and took another 5 lt. The charge I put in to the boiler was made up of such things as ouzo coffee liqueur and other simller very strong sweet flavored spirits. I thought I might have got some flavor carry over but was serprized with how clean it realy was. @punkin I had my gas burner on max low any lower it would have been off. If my phone was not flat I would have timed it to see how quick 1 lt was.

Im now prity keen to get 2 more plates and see how that runs with the gas. I probly got lots of questions but at the moment I realy only have one main one to ask. The take of speed was prity slow any suggestions on how to speed it up with out sacrificing my abv level. I can live with the speed but quicker would be nicer.

http://www.stilldragon.com.au/

A 4" Dash is, in my experience, capable of producing up to about 4 liters per hour working with a low wines charge. At that rate the product can tend to have the fractions smeared together. More reflux is needed to keep the hearts suppressed until the heads are drawn off and then again for the tails to be push back from the hearts. To keep production at this goal you need more boiler power and more reflux.

I tend to draw off at about 3 liters per hour to conserve water. That's about a gallon and a half of sipping booze per hour, ain't nothing wrong with that.

Adjust your dephlem to the highest flow rate that you are comfortable with and increase the boiler power until the dephlem can no longer knock it all down. That's pretty close to the sweet spot. Don't touch the power again throughout the run, instead fiddle with the water supply valve to regulate the production speed.

And congrats on recycling those failed experiments into something useful.

Thanks for the advice @Lloyd. I can pump a lot of water through the reflux. I am running a davey water pump. If I was to crank up my gas burner I can make the bottom of the keg rim glow. Think the next time I run it I will try about 50% power and see how we go. I am still not sure on the compresion of heads and how that is working for me. Remember Im a pot stiller.

http://www.stilldragon.com.au/

That's the beauty of the beast @Drunkas. Just run it a little on the hard side and don't be too timid. Knock it all down with reflux for 15 to 20 minutes and slowly increase the power until you get a few drops per second. Keep that setting power setting for the duration and after 15 to 20 minutes your heads will be really compressed. From then on just use the water valve to control takeoff speed. I take the heads off slowly to increase the hearts cut. When you are into hearts you can increase production but as tails approach (bottom lens begins to fog and production slows) give it a tad more reflux to suppress the tails.

I don't recycle my heads or tails from a spirit run from low wines. Some folks do but that's just nasty. A heads only recycle run might be OK though.

A controller will make a world of difference.

Could not agree more @olddog. I absolutely LOVE my automation controller.

The only problem now is I have to get out of my chair a couple of times to enter in the new settings from fores to heads to hearts.

Do I sound spoiled?

CouldHaveMountedTheControllerCloserToMyChair

Yes I have all the bits to build controller. Was planing on sending @olddog PM about it later. I been doing lots of collecting over the last few months all in the direction of building my self a realy nice and respectable home brewing and stilling setup. So I can make my own beer's and spirits all from raw ingredients. Even herb gardens so I can make my own flavored spirits.

http://www.stilldragon.com.au/

GB4 in your future? :D

BlatantShamelessSalesPitchOfSDproduct

Only one reply for you (Fuck Yeah) Give it 6 to 12 months and I will have one.

http://www.stilldragon.com.au/

Give it 6 to 12 months and I'll have to build more by then.

We just produced another 70 units with 40 spoken for and shipped out. Trying to keep ahead without over doing it. The kits are expensive and difficult to produce and package but we are getting better and faster at it.

So many unique parts and all of the boxes are designed to protect the filter baskets from the heavy housing. Assembly and packaging of the GB4 is challenging but it is a very special bit of distilling kit.

AgainBlatantShamelessSalesPitchOfSDproduct

Im in no hurry mate rome was not built in a day and I still got lots to lern plus the herb gardens need to be fully ready. Have I mentioned I only been in this hobby for little over a year. I got a list as long as me arm (and I got long arms) of gear I want from SD.

http://www.stilldragon.com.au/

planing on making a small box to house this gear in. Its a 2400 watt ell that i picked up sometime back

http://www.stilldragon.com.au/

You have the makings of a very fine controller there @Drunkas.

Please feel free to start a build thread for your project.

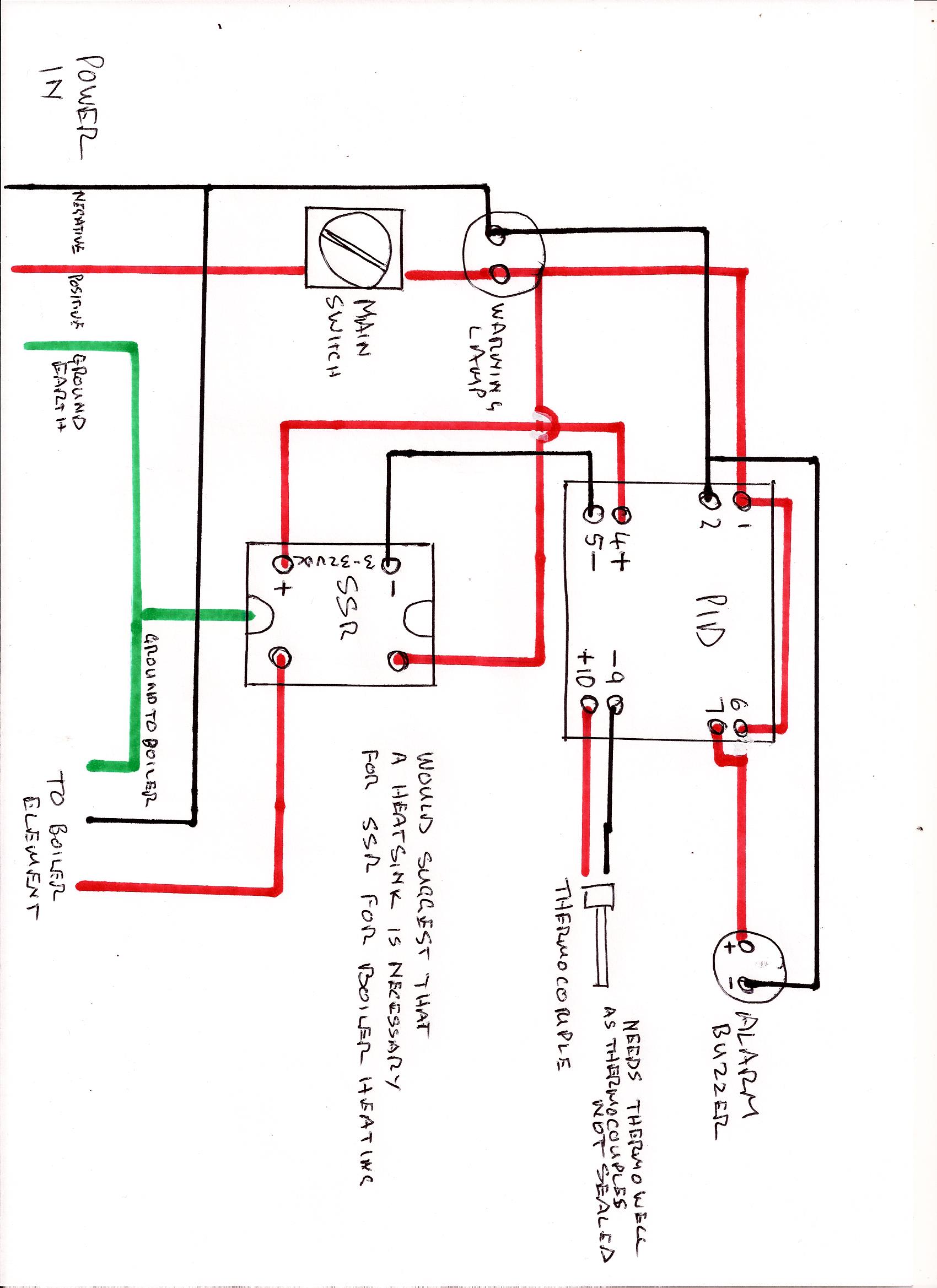

Here ya go Drunkas this should get you started. Just PM me your email addy and I will send you the manual for that PID.

Excellent @olddog.

I took the liberty of laying it out in Paint because it will probably get passed around for quite some time.

This arrangement is not for a still boiler control, mashing only

I first thought that I could use this build projec for both my boiler and mashing but sadly I had to chose one or the other. So Im building the controller for mashing.

http://www.stilldragon.com.au/

Would the same basic design also work for controlling a dephlegmator?

Use an electric valve instead of an element? Remove the alarm and warning lamp...