Welcome!

Be part of our community & join our international next generation forum now!

Categories

In this Discussion

- Cambo March 2014

- captainshooch January 2014

- Chalmer May 2014

- cleadus1 May 2014

- CothermanDistilling February 2014

- dad February 2014

- fadge January 2014

- FullySilenced February 2014

- irishman April 2014

- jonno January 2014

- Lloyd May 2014

- Myles April 2014

- Nake February 2014

- olddog April 2014

- Philter April 2014

- punkin April 2014

- rossco January 2014

- SDeurope May 2014

- Smaug April 2014

- what March 2014

Comments

I have been traveling for the past few weeks in France, so am a bit out of touch. Has anyone built a dual outport port hybrid yet? Permanently fitted packed column over a plated section, with two take off points. 1 above the highest plate, and 1 above the packed section?

No.

But maybe you can point the way?

I am working on a 5" hybrid at the moment but no plans as yet for a dual takeoff port.

Is it just for taking heads from one condenser and leaving the other condenser for clean hearts?

Dang, that means 2 product condensers and 2 parrots.

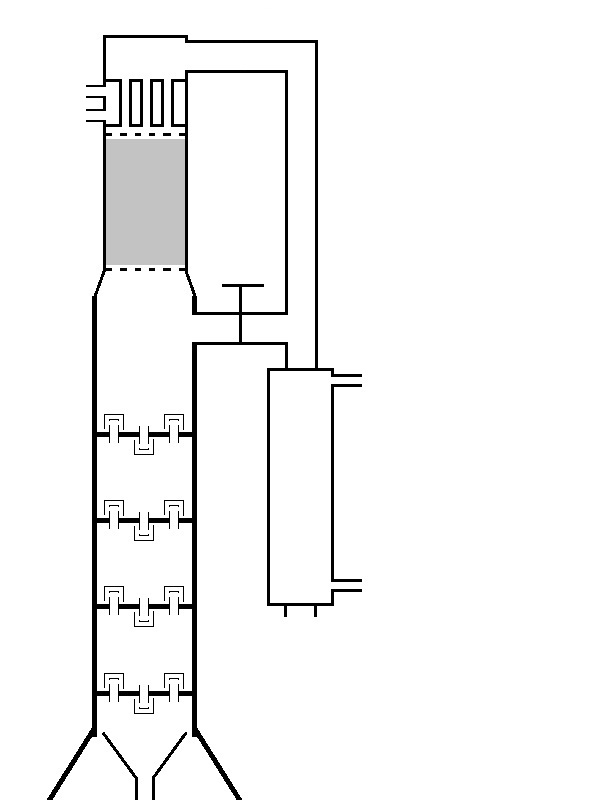

Sorry Lloyd been pre-occupied. How about this?

1 CM output and 1 VM output, shared condenser, single parrot.

Just to give two different products, flavoured from the plates and Neutral from the hybrid.

I suppose you could do this with just 1 output, but it all depends. Can you turn down the dephlegmator far enough so that you get a flavoured product out of the hybrid, and still provide enough reflux for the plates.

I suspect the answer would be - yes you can. :-j

Brilliant concept @Myles. Might be tricky with modular to get the bits right instead of bespoke and hand soldered together.

I would think you could do it if you soldered your own copper extension using the brass ferrules to get the distance right from the top of the plates to the take-off side.

Height would be easy to match up with the equivalent mating parts on both sides of the column. You'd just need to have a T on both sides right above the reducer on the top of the plates, or reduce down after the T on the condenser side.

As I mentioned though I suspect unnecessary. I haven't tried it myself yet, but I suspect the dephlegmator will have sufficient control to keep the plates in operation in both modes - when combined with power management.

I suspect the tricky part will be matching the packing density so that the vapour speed is also appropriate for the plates.

This might be a much simpler option to avoid removing and fitting the packed section and to avoid some of the packing density issues.

Simply bypass the packed section when running just the plates for a flavoured product.

All really easy to do with standard parts if you don't use a reducer. Just need a 2"branch ie extra tee, where ever you want the takeoff.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

5" crystal hybrid?

4 plates and a packed section all in a crystal column. YUMMY!!

I'm not doing something right because I could barely get 2 liters per hour of azeotrope but the SPP packing was not meant to be put into a 4" column.

I'm told by the maker it's for 2" or 3" columns. Only run it once so far so maybe (probably) it's user incompetence.

It could also be that there was only about 3 liters of potential alcohol in the boiler for the test so after loading the column it may have been starving.

There is another oddity that you need to be aware of with SPP. It is so efficient that it does not seem to like being fed with vapour that is TOO high in ABV.

You can run it over a single plate or thumper, from a wash boiler charge and it works fine.

However, with too high a proof charge (or possibly multiple plates) you get to a point where it creates azeotrope in a few cm, and this then disrupts the thermal gradient in the packing and leads to flooding and other issues.

Strangely enough this packing may not be the best choice for a hybrid. In my opinion it does 1 job very well. It converts fermented wash into azeotrope with between 50cm and 1.2m of packing.

But that is all. In any other application I would think twice before using it.

Possibly a silly question but if spp above the plates can upset the thermal gradient because of its efficiency why not use that to our advantage and use a shorter wider spp section above the plates, fill a torpedo made from a pair of 6>4 reducers

Not a silly question at all. It MIGHT be an option, I just wished to point out that SPP is not a universal solution. In this specific hybrid mode of operation it may well be that a different packing material works better.

SPP is best when it is operating in what most folks would consider to be a "flooded column" environment. This might not work out to be an appropriate vapour speed and reflux rate for the plates.

For a hybrid you really need to get the conditions right for the plates, and add packing so it does not adversely affect the plate conditions. May need a lot of trial and error.

There a lot of people using scoria in the hybrids with good success.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

+1 on scoria

My favorite compared to copper mesh and SS scrubbies.

Scoria Rocks !!!! :))

I'll chime in on the size or proportionate size of the SPP.

My home made Heli-pak is almost twice size of the current factory distiller stars shapes. Laboratories have three sizes for dif size columns.

Attached is a pic of the difference between size "A" stars (designed for a 1" column) and size "C" Heli-pak (designed for 2.5" column). Because I cut my bits by hand, the length is a little more "random" than machine cut.

How tightly the SPP is packed is also variable. I have gone from having it so loosely pack that it rattled, to tapping the column during install and getting another liter in.

SPP also creates a very solid thermal mass...the temp is very constant from top to bottom of the SPP section.

Then...the SPP will be shedding water down on the plates below. More/purer water than say scrubbies.

Your pic has 4 bubble plates and maybe 20 Theoretical Plates of SPP.

I imagine matching the vapor speed to optimize the two, to be very interesting.

DAD... not yours.. ah, hell... I don't know...

I keep staring at the picture...what if the dephlag was on top of the plates and under the SPP?

Run the Bubblers as normal and see what the SPP Section adds without induced reflux...I bet we'd all be amazed!

I have run my 3" x 36" column (30"s of SPP) without reflux and can average 86% heads through early tails.

DAD... not yours.. ah, hell... I don't know...

@dad that does sound interesting and easy to reconfigure.

I'm shut down for the next couple of weeks during the move into a bigger warehouse but I will try that when we get settled in.

5" stuff is now in the pipeline.

5" CD as well as SS Tees.

5" copper plates and 5" dephlegmators are being produced now.

And 5" x 6, 4, 3 and 2 reducers are also being produced.

As per @punkin, I'm prototyping a 4" x 510mm product shotgun condenser in advance of production. For those that crave supreme knockdown power in a compact shell you have Punkin to thank once it gets past the trials.

I figure 2 to 4 months for general availability on the 5" stuff depending on your distributor and his next sea freight delivery.

The new bubble tech will be introduced when the 5" debuts.

Should be quite a splash.

Ooooo the 4 inch product condenser sounds sexy. I'll order one of those for sure when they come out! Maybe two ;)

Everything is coming together so fast now!

A friend in Beijing sent 2 Camco 6Kw elements (the still area now has 60 amp service), @olddog's controller will arrive almost anytime now, and most of the 5" prototype parts can be cobbled together to make one heck of a still.

I don't really think a 4" product condenser is needed on this 5" column but I may opt for the 3" just to save water.

The 5" dephlem prototype is still probably 2 weeks away but the new 5" plates will be ready next week.

We I do get @olddog's controller I'll need to get a few custom pieces made to accept the sensors.

I agree that with the output the 3" system is going to be the superior one.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

Well, bugger. The controller has not arrived yet and probably won't until Monday.

I don't NEED it I just WANT it, haha. When it arrives I'll get a real electrician to hook it up. I know I can do it but I've successfully outlived many other electrical DIYers. :))

The dude ran a dedicated circuit from my breaker box to my stillin area and installed 3 power points from a new 60 amp mains breaker. Labor and materials was about $30 for all that! It's not worth me risking life or property to save $10 to $15. ($20 maybe, but not $15).

I wish I could get deliveries from China as quick as the time it has taken to get from OZ to you.

Its a crap shoot @olddog. Some deliveries are lightening fast and others (if you really, really need them) are slow as molasses in winter.

The problem is the time it takes to get moved once in Australia. I've tracked plenty of express deliveries from China that take longer to get the 5 hours by road from Sydney to here than it does from China to Sydney.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

Exactly right, it seems to take longer to get from Shanghai to me than from Australia to Shanghai.

It could be customs clearance and handing off to the local carrier that is causing the delay.

Its tons easier getting something out of China instead of in.

A friend sent small bottles of booze and some sweets not long ago. The delivery took a couple of months! The booze was not opened but the sweets were obviously sampled :))

I'm trying not to explode and keep the new 5" stuff under wraps until the distributors can be stocked. Only weeks away now as testing and modifications are done and production is finally in full swing.

Not sure this is a game changer or not but jeez I've spent a lot of time and money on it's development. I'll feel really bad if this one is anything less than the SD fully modular concept. Yet I know that hyping a new and unproven product has its risks but it is hard to be low-key when something so radical is in the pipeline. I'm itching to share it with the members here but the copycats are more than just fond of StillDragon, they rely on us for all of their "ideas".

Soon, my fellow distillers, soon. All I can say for now is that the new plate system is built from the ground up, discarding all previous concepts, to accept all the power that you want to throw at it.

At least half of my bright ideas are duds and the other half have been wildly popular. If only I knew ahead of time which ones were gold and which were duds it would certainly save a lot of effort but it's usually fun either way.

Stayed tuned... more goodies are definitely coming at you and it's very cool stuff.

Yes mate, i'm so looking forward to seeing both the parts and the stir they are going to generate. I really think you are right to wait till we have the gear.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

Lloyd it must be pretty spectacular to top a crystal dragon

Now I'm just guessing but that 4" condenser in development wouldnt be a punkindensor would it Please please please......