Home › General › Accessories

Welcome!

Be part of our community & join our international next generation forum now!

Categories

In this Discussion

- 211 November 2013

- awesome October 2013

- bentstick October 2013

- brewsmith June 2014

- bronco October 2016

- captainshooch March 2014

- cooperville January 2014

- CothermanDistilling May 2014

- crozdog February 2014

- cunnyfunt May 2014

- dad May 2014

- devilshine February 2015

- DistilliTraK April 2014

- Drunkas October 2014

- Duck0fDeath January 2014

- EdInNH March 2014

- fadge March 2014

- FloridaCracker October 2016

- fnulnu February 2014

- FullySilenced October 2014

- Goinbroke2 March 2014

- googe May 2014

- grim October 2016

- Grip October 2014

- irishman May 2014

- jacksonbrown October 2016

- jbierling February 2014

- Jung October 2014

- Kapea October 2016

- kimbodious October 2016

- Law_Of_Ohms March 2014

- Lloyd November 2014

- lowball April 2014

- luckyliqueur November 2013

- Manofconstantsorrow February 2014

- Mickiboi March 2014

- Myles February 2015

- nvnovrts November 2013

- olddog January 2014

- Philter March 2014

- punkin May 2014

- RedDoorDistillery November 2013

- Sandman September 2014

- SDeurope March 2014

- Smaug May 2014

- TheMechWarrior October 2014

- thunder88 November 2013

- Tombstone October 2016

- Unsensibel October 2016

- waxernz April 2014

- YHB October 2013

Loony bin and crazy ideas

in Accessories

A place to put brain farts. Feel free to contribute a few of your own here!

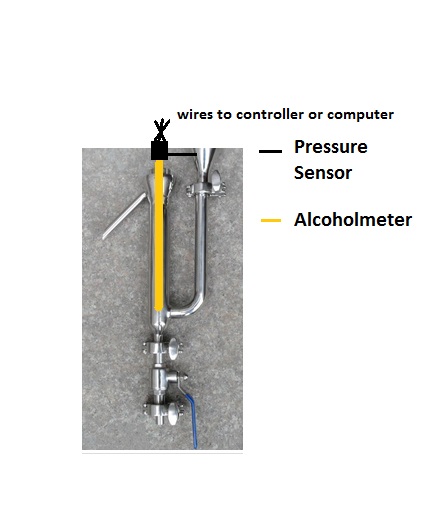

The idea is to have a digital input for the ABV of the distilled product output.

I know you can measure vapor temperature and calculate ABV and that is probably cheaper and easier.

Anyway, the idea is the alco pushes up on a sensor and the sensor sends the electronic signal to the controller.

The less ABV in the parrot the less pressure is exerted on the sensor.

Am I bonkers?

crazy1.jpg

447 x 517 - 37K

Comments

Yea, how about the alc meter has sensors spots and a "reader" just takes these and lets you use it at whatever purpose. you need. As it floats up and down it measures differently, almost like a tank level indicator unsure just how accurate it may be how-ever.?

fadge

Wouldn't one also need to know the temp of the distillate and apply the correction factor to be accurate ? I like the idea of feeding data wireless to a tablet or a laptop (I can't imagine why ;) )

Hobby Distillers Association Member - Join us today!

The only sillae question is the one you don't ask folks...

You guys get it!

And since this is the Loony Bin...

The sensor spots could be put INSIDE the alco glass while its being made.

Imagine a barcode thingy and a barcode reader.

Very cool concept! Would be a very good addition to my computer for runs,another way of precision. :)>-

It is what you make it!

Its called a linear encoder. This would have to be an optical linear encoder rather than a magnetic / hall effect version.

Not so loonie.

I've thought about it already! lol

There seems to be nothing on the market apart from an ethanol refractometer taking samples.

https://www.youtube.com/watch?v=ty6eY9VUIgI

Need to develop an app for our smartphones. They can read barcodes, so why couldn't an app be set up to read the level indicated on the meter(just need alignment right). If they are tethered I don't see why they couldn't feed back info to computer, another tablet, or I'm sure it could handle the process itself.

And there it is! :)>- one place to start!

It is what you make it!

How about a camera (webcam?) that could count the number of lines on the alco?

A bokakob module containing just the slant plates, So to turn a 2'' pot into a boka. Just put 1 or 3 2" 500mm spools packed with scrubiis on your keg add the boka module then repurpose your product condenser as a reflux condenser instead of a coil, bingo instant boka. Or even cooler use 2" borosiliciate glass tube Worlds first Crystal Bokakob.

Everytime I bring up the subject of a boka module to the SD core I get slapped back into the corner.

They remind me of how painfully slow it is to run but you must be in tune with my mental wavelength, @211, because I was thinking on it yesterday and again today. I DIDN'T think of a crystal boka though.

It's a clever idea and I'm willing to get another bludgeoning by bringing it up again.

Disclaimer: I have never, not once, run a boka so the opinions and experience of others have a strong influence.

Would a crystal boka have enough insulating factor for no need of insulation? If not I think it would be almost impossible to run one for the fact of trying to get it and keep it equalized with out separations collapsing! Sorry just a thought. :-? Would be cool to see the interior of one running!

It is what you make it!

Odin's unit is a boka and he has a glass one running ... look for the video...

and yes a boka module should be made would not be expensive and jeez ya can't sell it if ya don't have it...

You could have just the head in a sight tower and still insulate a stainless column. Biggest trouble would be getting the off take, but it would be good to see the reflux rate.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

You could drill a hole in the glass easy enough but you couldn't hang any weight, like a condenser, from it.

VB drew this up for me a couple of years ago but it still beats me how I can have it produced in stainless. It's impossible to fully polish the nooks so it will discolor and everyone starts yelling rust.

Anyway, the idea is the module as shown could be both LM and VM. Remove the heads so they don't contaminate the VM gear. You could also flip the module over and it would be VM only. The arrow at the top right marks a drain hole to make that possible.

@Lloyd, Wouldn't electropolishing get all the nooks?

Just throwing a few ideas out there for the crystal boka. Could you bond the glass to some stainless and make an inline sight glass type unit with a side view of the plate. Or dril the holes in the glass and then internally or externally bond or mount cut away stainless inners liners to it and seal it all up.

Electropolishing is great. It removes the burn marks but does not leave the surface as smooth as real polishing. Unless it is very smooth it will rust.

I don't know how to bond glass to stainless steel. And remember, I must do quantity. No factory here will do special orders for just 10 of something strange.

That could be an option. Especially if both inserts are exactly the same, just turn one over.

Make the plates so that they press in the tubes mount them in rings... may be a solution

Picture?

Do one big bubble cap for the bubble caps, put a handle on it so that you have a simmer and a boil option for the bubble plates. Already have a hole for a thermowell in some of the T's.Handel far left is off and the cap is open, middle and the cap is at 50% depth, far right and the cap is all the way down on the plate and at "boil". you could engage/disengage the plates at will. (I was reading the Holstein catalog last night)

on @FullySilenced 's idea, have a piece of copper or stainless punched/water-jetted into a shape that can be pressed round and inserted into the glass. the shape will have the half-ellipses stay flat, but the area around them pressed into a curved surface that will hold the plates in place.. dont have time to draw it, but if you fabbed it up out of paper, then laid it flat, it would give you a good visual reference..

If you did 4 or five of these in a crystal, have them drip like downcomers, and you still take off above the dephleg... way cheaper than a bubble plate since could be single cut and press from copper sheet

errr... difficult to seal on sides of glass, might be an issue

...and the glass is not perfectly round.

As a suggestion why not make it square to start with and get some working values two sides can be plate glass two sides can be copper ( stainless ) in the metal sides we can put in our fittings when we have a working prototype then consider how to make it round

Now that's thinking "inside/ouside" the box, would need a square to round adaptation to allow everything else to connect.

Or maybe glass inserts melted onto the inside wall of the glass cylinder?

Getting a valve fitting in the collection hole (bottom left of the sketch) could be a problem.

Hi All,

I have been following this site since the beginning but it is all bubbler's - now slant plates - that's a different matter altogether.

I am currently far away from home and my PC, I have not got much in the way of editing software with me - so apologies for the size of the pictures etc.

Maybe not enough glass but you will be able to see everything, just have to move your head.

Toodlepip

Brian

Why can't you use the stainless base to tap the takeoff? It's too hard to tap the glass. You would still be able to see everything.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

I thought that was what I was trying to show, must try harder?

Use one hole for the take off, other for temperature probe / thermometer.

Sorry mate yes, just like that. I am on my phone and the pics were hard to make out.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

How about if the coil was glass too, make the whole top section of glass, Then the output could be pushed into a silicon tube and instead of a needle valve you could control output with one of those clamp things like a nurse uses to control the drip rate of a iv line. The whole thing could just sit on the top of a 2" triclamp spool. With a epdm o ring giving a seal.