Welcome!

Be part of our community & join our international next generation forum now!

Categories

In this Discussion

- FloridaCracker August 2021

- Jung May 2021

[USA/MN] Sale: 4" Original SD Bubble Plate Still System with 6 Plates, 8 Tee Sections, etc

Multiple job changes, addition of 3 kids, and some health stuff has me giving up some old hobbies, including home brewing and dabbling in distilling. This setup took many years to build up, but I'd love to pass it on it one big collection, at what I think is a very fair price. If you want to sell off what you don't need, great, I just don't have time and motivation to do that.

So this was built after nearly decade of brewing on the 1st system I built up and just skipped to "whoa" level right away compared to how I start with partial boil extract brewing, so this will take a second to lay out what's included and has never been shared online.

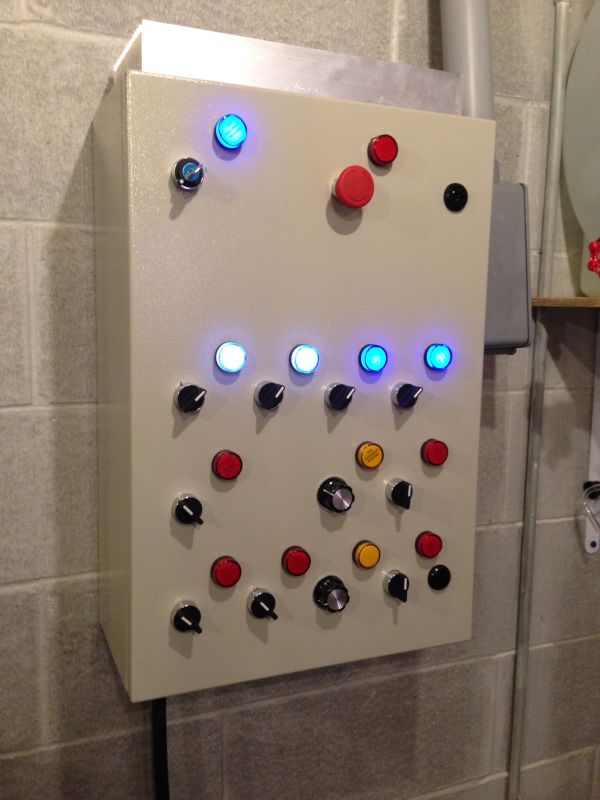

The biggest highlights outside of the Still of course, is the control panel.

We’ll start with power and control panel

I have 6 electronic circuits dedicated to the brewery:

- 5 x 30A 220V (1 each for HLT, BK, Heat Exchanger and 2 for the Still)

- 1 x 15A 110V (For controller, pumps, lights and exhaust fan).

The heart of the panel is the BCS-460 by embedded control concepts which allows web browser based control and monitoring of the system. It has temp probes currently in the HLT, HE, and BK for monitoring. I was planning to add another somewhere in the still setup, but never got that far.

All 6 circuits enter a large wall mounted NEMA panel via 2” Conduit.

The 220v circuits each pass through 2 pole 110v coil 40A contactors before then going to either a solid state relay or a phase angle controller. The relays are controlled by the BCS-460 and the contactors are controlled by switches on the front of the panel for double safe standards.

The lights, fan, and pumps are simply wired directly to the switches. All of the heating elements except the boil kettle are hard wired directly to the panel for simplicity and cost savings. The Boil Kettle as a cord hard wired to the BK position with a Twist Lock 30amp outlet on it to ease disconnecting and cleaning.

Has a ethernet jack for connecting to your network and 1/8" jacks for the temp probes.

Brewing setup

4 vessel E-Herms setup, so:

- 5500 Watt HLT - 1/2 Barrel Keg, flipped with 4" ferrule welded on the bottom as a lid and sight glass tube tee welded on for the temp probe

- 5500 Watt Heat Exchanger - Corny Keg with heating element in the bottom and drain valve - 1/2" Copper Coil with temp probe slides in (Note that I like this vessel separate so you can have more control over the mash temp and be able to have a different temp in the HLT for sparge water

- Mash Tun - 1/2 Barrel Keg with full size, folding false bottom and stainless valves. I made a little copper manifold and attached it to a pot lid that goes on here for recirculating the mash. It worked great and would keep mash within a degree of target -5500 Watt Boil Kettle - 1/2 Barrel Keg with False Bottom AND a stainless hop filter basket - just a standard keggle here

- 2x SS Chugger Pumps

- Therminator for Cooling

- Thrumometer for monitoring cooling

- 1/2" Quick Disconnects (stainless) for the plumbing portions

- Barley Crusher

- Cooler Style Mash Tun for Corn mash that doesn't recirculate as well (older version of this)

- Custom Welded Steel Stand houses the whole thing very securely and has bolts for feet for leveling

Still Setup

Still Pot - 11,000 watt via 2x ULWD 5500 watt elements in a 1/2 barrel keg flipped and welded with a 4" ferrule on top and a drain out the original top.

Some of the Still parts (mostly SD):

- 8x 4” Sight Towers with SGK - Original Brass Versions

- 4” Reduced Height tee

- 6x Old version Bubble Plates (4”)

- 4” x 20” Tube (with 4 lbs of copper mesh packed in)

- 2x 4” 90 degree bends

- 2x 2” 90 degree bends

- 2x 2” 45 degree bends

- 2” Shotgun Product Condenser

- 2x 4” Dephlegmator

- 2x 4”x2” Reducer

- 4”x2” Torpedo

- 2”x3/4” Reducer

- 4”x2” Short Reducer

- 2”x3/4” Short Reducer

- 2x Gin Baskets (NEVER USED) - With the above parts, you can create the Gin Basket Setup with Drain

- Custom copper parrot with a 3/4” Triclamp fitting

- And lots of tri-clamps (16 - 4", 12 - 2", etc) , gaskets, and plumbing parts

Fermentation (at least what I'm including)

- Small-ish O2 Tank and Regulator - Needs new stainless diffusor stone

- 2 or 3 Glass Carboys

- Several Airlocks

Bottling

- Fast Rack Bottle Dry System

- Old Style Beer Gun (Blichmann)

- 3 Ball Lock Corny Kegs

- Portable Corny Kegs with CO2 charger and Tap with Neoprene Sleeves

Misc

I'm basically planning to include everything I can pull together that goes with this hobby...

- Ultrasonic Bath for treating the still product

- Copper Mesh for packing still column

- Mason Jars

- Bottles

- Several Keg Fittings (from my beer dispensing days)

- Spare Connects, Quick Disconnects, Stainless ferrules etc.

I've got WAY more into everything, but to try to make this easy, I'd sell EVERYTHING for steal of a deal:

Asking $3,000 in Minnesota, west of Minneapolis a bit. This is too much to ship, so pick up is needed. Could be a great little test setup for a new distillery or a brewery that wants to see if they should expand into distilling.

As a bonus, I'll even include my original SD Large Copper Funnel (w/ 2" TC ferrule soldered on), that thing is just cool.

Pics show a few glances at it from over the years and the still parts laid out just yesterday.

Comments

I found a few more pics with the funnel shown on the still pot and the inside of the control panel I built for this setup.

WOW! That panel is sick.

GLWTS