Advice on Wash Feed

"Qualitatively", what is the best feed solution to a RIMS boiler for steam vapour for an intended continuous stripping column. Or does it not make a difference?

Options are:

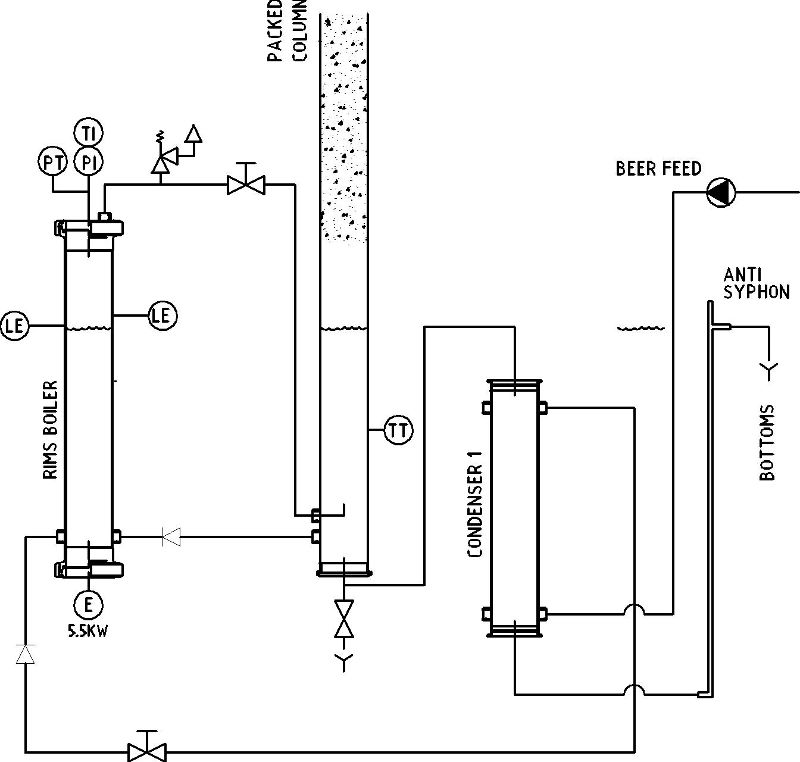

- Heated beer wash to Rims boiler

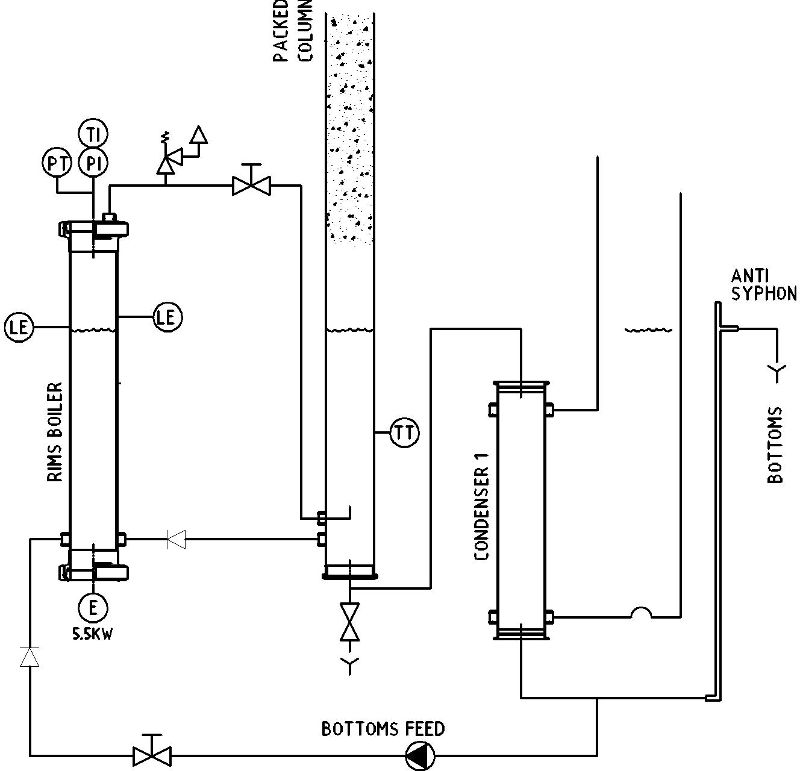

- Bottoms supply to Rims boiler

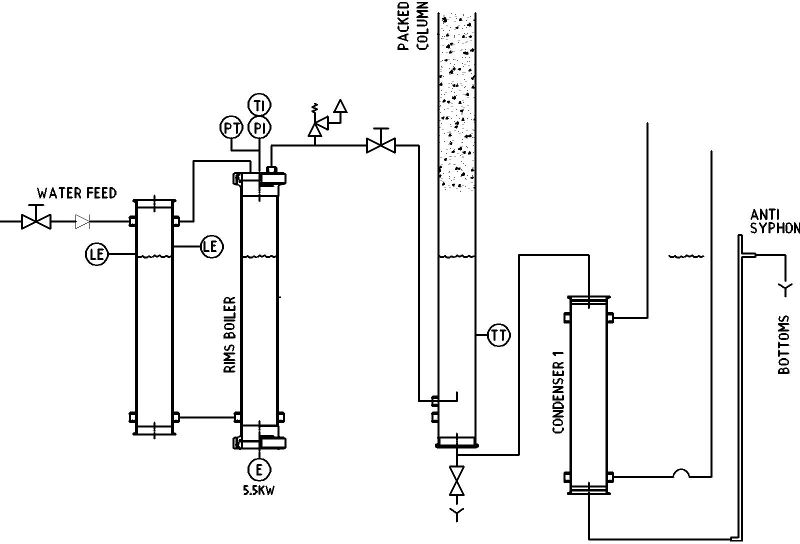

- Cold water to Rims boiler

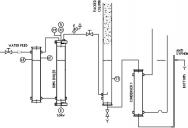

I have shown the above 3 in very simple drawings to explain what my enquiry is about. The drawings are not exact but helps show what I am trying to ask.

My intended option is the first one for heated beer supply. My concern however is that this may give possible taste taints by comparison to water with a clean steam supply.

The problem with cold water supply is that it requires an "extra" amount of heat up by comparison to the prior two.

Thoughts anyone ??

1.jpg

800 x 771 - 46K

2.jpg

800 x 762 - 49K

3.jpg

800 x 544 - 33K

Comments

Will the beer feed contain a high solids load like a grain-in wash?

No, it is not intended at present for a high solids content. If it were, I would aim to strain it out as much as possible.

Eliminate a considerable amount of complexity and simply put the heating element in the bottom of the column. Ensure your bottoms take off is above the top of the element to keep it submerged (your designs already account for this). You'll probably need a sightglass to validate that your beer feed volume is sufficient to keep your reboiler topped.

Call this a directly heated reboiler, vs your designs which are all indirectly heated.

Simpler, more efficient, more responsive to power input changes, likely a higher abv output vs steam injection.

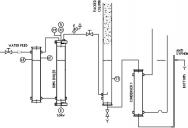

I am suggesting a simplification of your "Bottom - Model" print, which would be considered a kind of thermosyphon reboiler design. The image shows a steam powered reboiler, but the concept is the same using an element. Note that you need absolutely no valving on the steam feed back to the column - which should be above the liquid line - not below it as you have displayed.

Actually, your "Bottom - Model" print will not work at all - this is why you can't restrict the steam flow back to the column bottom, nor can you use any one-way check valving.

Thanks for the response.

Some quick answers. Firstly... The bottom line with check valve was only intended for start up for flooding when there is no system pressure. Secondly ... It was the thought / intention to take the Rims boiler up to as high pressure as possible and then by means of the throttled valve and power supply control the heating conditions.

If I were to take the element to the bottom of the column, the entire system would become atmospheric. I had based the concept of the boiler part being under pressure.

The thought behind the submerged entry was to get the bottoms up to boiling temperature.

The more detailed system is shown below.

Put the element in the bottom of the column and get rid of all that unnecessary plumbing and complexity.

Control the bottoms power input directly from the element.

You don't need pressure control - steam injection - etc. adding complexity with zero benefit if you are not dealing with solids.