Home › General › Accessories

Welcome!

Be part of our community & join our international next generation forum now!

Categories

In this Discussion

- bentstick November 2013

- CothermanDistilling November 2013

- Gil_flask August 2013

- Law_Of_Ohms August 2013

- LunaBrille August 2013

- nvnovrts November 2013

- olddog August 2013

- RedDoorDistillery November 2013

- salientlucidity November 2013

Temperature Meter

I've been in the planning stages of an all in one control station to suit my needs. I'm looking at replacing my dial thermos and adding PT100s to my column, cooling water tank and boiler. I've thought about automating some things but I'm not really ready for that. So instead of a PiD I found these, looks like it would save some space and they aren't to expensive. Have any of you guys had any experience with these or know of something better?

Digital DC Temperature Meter for 4 Temperature Sensors (4 x RTD PT100 / F)

Tagged:

Comments

Unbranded with no model number, I cant see a refresh rate - It would annoy me if it only updated every 5 - 10 seconds...

https://www.youtube.com/watch?v=ty6eY9VUIgI

I would not have even thought of that! Very good question. It looked cool though.

I am currently putting together a controller using a PID and solenoid valves to control the reflux rate of my dephleg.

@olddog at some point I'm going to take the plunge and delve into that arena. I have what my friends call creeping feature-itus. =)) always looking for the next upgrade. I hope you document your efforts, I would love to follow along and learn.

@law_of_ohms I emailed the seller to see if I can get the refresh rate and other specs. After thinking on it all day I think I can live with a few seconds delay, but it would be nice to have real time. I'll keep you posted as to what I hear back.

I will post a few more details as the build progresses. At the moment I am trying to find an adjustable pressure relief valve, if I can find the right one I will be able to make the system fully controlled from the panel with no manual valves in the system.

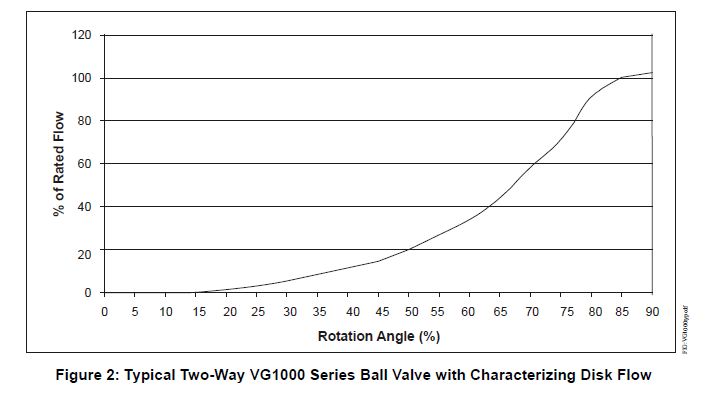

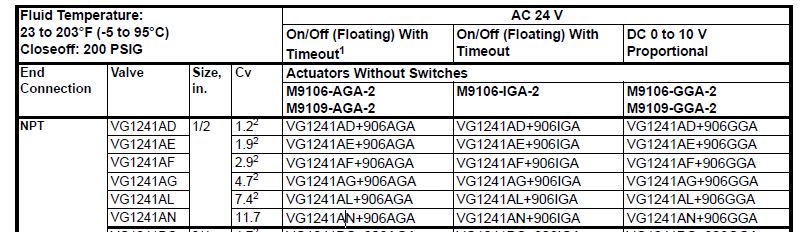

I am looking into that as well right now. Below is the valve I plan to use. It is a True PROPORTIONAL valve. And will allow up to 7.4gpm flow rate.

VG1241AL+9T4GGA Johnson Controls VALVE / ACTUATOR

Looked but cannot find min flow ?

It is what you make it!

From the Flow Rate Chart looks like 15% so 1.1gpm. Keep in mind that I am putting this on a 8" column. They do make the same valve with in 1.1gpm, 1.9gpm, 2.9gpm, 4.7gpm max flow rates all in 1/2" connection. All of them are rated down to 15% flow min. They are spendy valves though...

@Law_Of_Ohms I heard back from the eBay seller, The sampling rate of this meter is 0.5 seconds. I'll step up and be the guinea pig and pick one up.

0.5 seconds should be good.

https://www.youtube.com/watch?v=ty6eY9VUIgI

with the valves for the water as well? Do you need a PiD to control it or just temperature probes?

I've been eying up these USB temp loggers for $14.40 each:

I'm hoping i can plug 3 or 4 into a USB Hub and log everything onto a laptop (unfortunately they are windows only but for the price I can put up with that).

I have 3 of these that just arrived that will be going into my control box along with my PID. This will give me Boiler, Head and Parrot Temps while the PID is giving me the Top Plate Temp and controlling the cooling water valve:

Digital DC Temperature Meter For RTD PT100 Temperature Sensors (C / 24VDC)

I am telling you guys, once you play with a BCS460(462), you will be hooked... for $180($280), you get ethernet, hugely programmable web interface, 4(8) temps, 6 PID's, process control, data-logging, can super-calibrate sensors, 4(8) digital inputs, 6(18) digital outputs ... embedded control concepts Granted, you still have to build the control panel, and add relays/SSR's/contactors/switches...

This is what I use,with 4 go temp probes: Vernier - Logger Lite

It is what you make it!

With a panel using the BCS, you can fill the boiler, turn on water supply, start the datalogger, press start, and wait for an alarm to tell you that the boiler is waiting at 170 or whatever for you to start... hit a button to continue heating, dephleg water solenoid activates when the vapor temp rises above 120 or so, timer to let you know you have stabilized for 30 minutes or whatever... (auto shut off when boiler, vapor, and/or parrot get to a certain temp..) just sit back, fine tune dephleg water and take cuts... added to the SD Dash, it is almost like cheating.. It leaves enough manual control to tinker, but takes care of the menial tasks..

The gold line is above the dephleg, the grey is below, and the black is before any plates.... notice above and below are not always the same...