Welcome!

Be part of our community & join our international next generation forum now!

Categories

In this Discussion

- CothermanDistilling December 2015

- grim December 2015

- HurdleCreek December 2015

- Kapea December 2015

- Kill_Devil_Spirit_Co December 2015

- punkin December 2015

- Smaug December 2015

The Dragon Breathes Fire

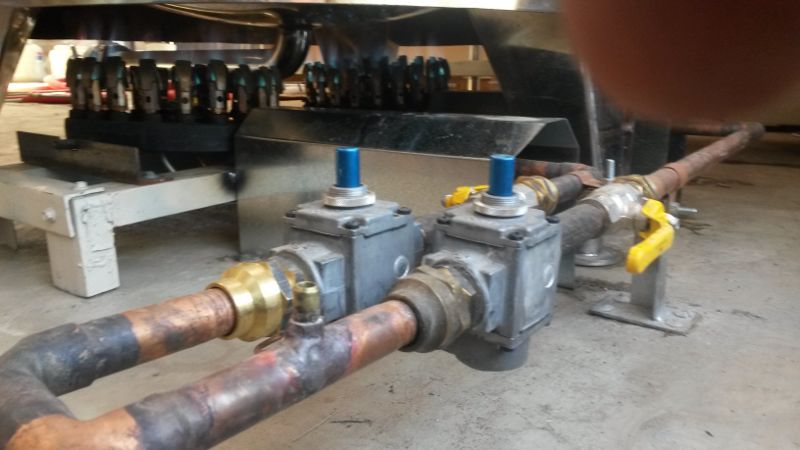

Its been a while coming but finally the gas firing is OK to go! Water commissioning run No.1 with gin basket in the line. 2 x 28 jet duckbilled burners. No problem getting up to temp!

1.jpg

800 x 600 - 66K

2.jpg

800 x 450 - 50K

3.jpg

800 x 450 - 38K

4.jpg

800 x 450 - 46K

5.jpg

450 x 800 - 55K

Tagged:

Comments

Nice.

StillDragon North America - Your StillDragon® Distributor for North America

What's with the conical fermenter? That's the gin basket?

What is the heat up time with that pair of manifolds?

StillDragon North America - Your StillDragon® Distributor for North America

You mean liftoff time? The guys from SpaceX want their booster engine back....

Is there an exhaust? my experience is everything within a few feet gets way, way too hot..

I have a professional brewer friend with a milk tank beer boil kettle that has a convex instead of concave bottom, and a jacket around it that is vented to the outside... it allows the drain to not be affected by the flame, and provides a path for exhaust gasses, I think the jacket has a spiral baffle to slow down the gasses...

Not the greatest pics... he has one burner that looks similar to those two..

Those flip flops are not OSHA compliant....

Look like regular work boots to me.

Loving the beast @HurdleCreek , it looks fantastic. The conical gin basket looks just like i imagined it would when you were telling me about it.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

Grim's right, I've adapted the conical to be the gin basket. Its a bit of home brewer's bling - 304, clamp down lid & even came with 1.5" triclovers on the drain, racking point and head, 50Lt brim full. Was going to put vapour in through the racking point by the angle meant it would've needed a second condense drain. Instead used a T onto the drain point with a single condense back to the pot

Cotherman, There's a 6" flue hiding behind the column. Comes out of a box tacked onto the skirt & straight up through the roof an a meter or so above it. Would've like a convex base but that was getting to complex. May look at some internal baffles at some point

How did you arrive at the elevation with which to set the tips of the jets away from the belly of the kettle?

StillDragon North America - Your StillDragon® Distributor for North America

Nothing very scientific. We built the frame using the steel frame the pot arrived on. Estimated the height we'd need before we saw the burners workin - made it higher rather than lower so we could cut it down if needed be. It seems to work.....

Thanks, I have had questions about the optimal height and just wondering how well your established elevation works.

Would you say that your jet tips are perhaps 2" (50 mm) away from the belly?

StillDragon North America - Your StillDragon® Distributor for North America

The conical is the best idea yet towards a larger gin basket.

Vapour inlet to gin basket

Official work boots round here!

Are you on the book of faces as a distillery Simon? Can't find you under your distillation business name.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

I am but not the distillery yet - been waiting for photos of an operating still and artwork (still in progress). Probably get around to it in next week...

Maybe closer to 80cm ~3" on the inside and 100cm 4" on the outer

I'm surprised all the electroheads aren't going apeshit over your open flame!

Those burners are awesome. I love applying high BTUs to metal like that. Does the boiler metal glow red, or do the flame defusers take care of that? Bet it sounds like a hot air balloon lifting off when you're heating up to temp.

I'm more like I am now than I was before.

I bit my tongue.

Well as long gone as the skirting is done properly and there's good ventilation I'm happy, though I would totally use this as an excuse to build a sweet brick furnace around it... you're sure as shit not gonna find a steam or electric Charentaise.

So long as there's enough liquid in the boiler nothing glows - haven't tried them with the boiler empty! The boiler guy who did the installation was more concerned about the skirt weld cracking due to differential expansion so min fill height it above the weld line. Have a couple of burns that testify to the heat in the skirt! The roar on full power is impressive.

Lloyd and punkin designed the skirt. Its solid and a good air gap. We put in a 6" flue that draws well. May build a brick hearth in future but for now it will make mods to the burners or the boiler v difficult. Insulating the skirt and boiler sides with glass wool batts improves efficiency by about 20-25% so for now may have to design a removable fireblanket overcoat to put on it when the burners are running - maybe with a big SD logo on it

I see you figured out the double space thing Simon.

Tell us about the agitator you had built in, have you tried it yet?

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

If you look on the rhs of the boiler you'll see a tangential 1. 5" pipe about halfway up with a butterfly valve on of. . It works just like a brewery whirlpool except you pump out of the center of the dish (so no trub cone) and back in through the side entry. Keeps everything moving the same way as an agitator.

Have tried it pumping through hoses with water but not with a hot wash yet. I've got a big centrifugal pump which makes it really spin if I open the outlet valve fully and some great new brewery hoses we picked up at Grays online from a craft brewery that ran out of finance before it got to brew. So it should be OK but never happy about pumping hot product around through hoses so will try to hard pipe it first if I can find the time...