Welcome!

Be part of our community & join our international next generation forum now!

Categories

In this Discussion

- FloridaCracker December 2015

- FullySilenced December 2015

- grim December 2015

- jacksonbrown December 2015

- Manofconstantsorrow December 2015

- Mickiboi December 2015

- popcorn December 2015

- punkin December 2015

- TheMechWarrior December 2015

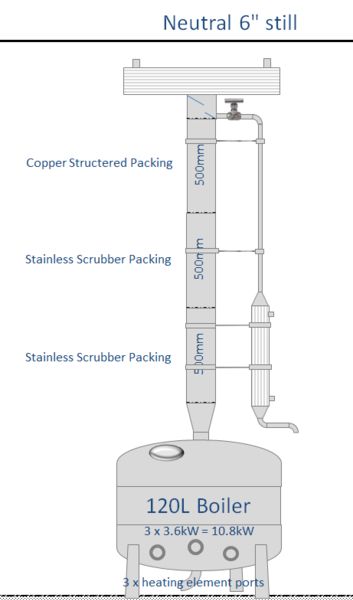

Neutral Packed Column 6" Rig

All,

Would appreciate your thoughts on the following design.

I had fully intended on a 6" VM (the Rolls Royce of neutral configs in my opinion) but I simply lack the ceiling height to pull off what I'd like to do.

I do have the room to run 3 x 500mm (20") packed sections.

To knock down the near 11kW of heat I'll need a 6" condenser x 570mm length (22").

I've included a 3" PC for good measure but in reality it should be overkill.

HETP = 12-15plates depending on the desired reflux rate.

I've shown a 1" off-take. I'm not happy with having to operate a valve so far off the ground; any ideas for being able to operate this from ground level appreciated.

I'll have this built and running before Christmas with your help and assistance.

Cheers,

TheMechWarrior

Comments

I wonder if you could use an electric valve for that and just control it remotely? I don't know if they have fine enough control for what you want is all.

I agree with you on the VM, but why can't you just put a bubbletee where the bok section is and use a valve there for VM?

Maybe a walkway instead of a ladder if you have room for it too?

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

True, the VM does in fact fit. But I'm still stuck with a high valve. In all my VM drawings I hadn't considered using the horizontal head condenser!

Just take off the handle and use a stem extension.

Get a bigger valve though, your vapour line looks way to small if it's to scale.

A 3" PC is a waste if getting fed by a 3/4" valve/vapour line.

The valve and off take is currently shown as a 1", in reality it would be a 1.5" since that's what I already have and I've run a 6" VM using a 1.5" gate valve in the past and it ran very nicely. I was only using the 3" since I had but you are right. I'm going to the trouble of custom making everything else, may as well make a suitable PC.

I found a 1" PC I made years ago, it's 1m long.

Can you install the valve upside down and use a stem extension to get it down to a workable height?

If you are talking VM and not LM, why does the valve need to be at the top? Technically it can be immediately before the condenser.

Also, if you are using a multi turn valve, replace the round handle with a cog, and run a length of chain down to a second low mounted cog with a handle. You won't have much slack in a chain, so you'll have good controllability.

Pooling issues on equilibrium? There's an auto reflux design that works a bit like that with a solenoid valve downstream of the PC and no vapour valve at all. Works by reducing the condensing area by flooding the PC. Not how I would do it but apparently it works OK.

I wonder how bad the smearing is?

All you get is foreshots from pooling when you first crack the valve. With 120l of 40%, 300ml of crap in the piping when bleeding foreshots won't be even noticed. It's a bloody good idea Grim. Who cares if you smear the foreshots into the heads?

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

I mentioned smearing in reference to the E-ARC design with a flooded PC. It runs like that all the time.

That's a lot of scrubbers... I've been browsing alibaba to see where I could get enough stainless packing.

I have all the packing here already. Nice and cheap, thanks to Bunnings.

I did ask a number of "professional" suppliers for quotes on structured packing for a 12" column and not a single supplier responded. So bugger 'em, we all know the scrubbers work a charm, I'll just do it in a 6" column.

I have 2 different sizes of scrubbers and the packing pattern is perfect. I have enough copper mesh for 800mm of packing, the remainder will be the staino scrubbers. By packing in fixed sections of 500mm it reduces the opportunities for excessive compaction.

PS @grim, I'll have a look at what can be done to remove the gate valve handle and replace with a chained wheel/lever/cog down to just above the boiler.

I need to complete the condenser drawing today so construction can commence tomorrow, will just round it up to 600mm.

Sprocket not Cog, the Jetsons forever confused me.

@TheMechWarrior I do suggest that you place your copper section to the first one (bottom) just above the boiler. Your copper will break down and it is better to leach to the tank rather than all over your stainless IMHO.

The day you quit learning is the day you start dying!

"I am an incurable gadgeteer, and I like enormously to set up a theory and then track down the consequences" Murray Leinster youtube.com/watch?v=08e9k-c91E8

I would also place the copper at the bottom. I bought 2lb from Amphora. I rolled up a good chunk of it and removed the appropriate amount of scrubbies from the top of the 1500mm column and put copper roll in. I had just finished a run and had no problem pulling azeo. So I was very suprised when all I could pull was around 90% using the second half of the strip. I put the still back into full reflux for 30 minutes and tried agin. Still 90%. In the beginning I discounted the effect the copper packing would have on the purity, I mean 1500mm column height, who would have thought. It started to do my head in. So I shut everything down and put my scrubbies back in. 95% straight away.

So I shut everything down again and pulled out 1/3 of the scrubbies, put the copper roll back in, packed the scrubbies back in, 92% and a bit. I shut everything down again and removed 2/3 of the scrubbies, put the copper roll back in, about 94%. Shut everything down again put the copper roll on the bottom, 95%.

The amphora copper mesh is very fine. Compared to the scrubbies you can almost see right through the roll. It makes a difference where you put this fine mesh in the column. I spent 12 hours mucking around with this. In the end I took it out. The surface area and surface tension of the copper mesh must be extremely, very, very small. Amphora don't give those figures. But if you put it at the top, expect to drop a few points at the parrot.

My results don't match yours and I suspect the reason is due to the way I rolled it. Nice and tight, it sits around 600g per roll in a 6"column.

Each roll sits at roughly 100mm in height.

So for a 500mm packed section you're looking at 5 x rolls for a total of 3kg of packing.

BTW I'm use the same Amphora 2lb roll.

I've always run with the copper as the last material the vapour sees and I've never seen an issue of decomposed copper residue built up on my stainless? Was that recommendation based on theory of practical observation?

Approx how many uses would you get from such fine mesh? Seems like they would wear out pretty quick. My copper scrubbies got pretty thin after maybe 6 or 7 cleanings and seemed to not want to completely clean. They would lose the black color but not go back to original color. Then again, neither do my copper plates/caps.

I rolled mine tight as well. I got more than 1lb to fit into my 4 inch column and it had to be shoved in. I gave it to Johnboy to try out. I'm over it. It was his suggestion to me after I sent him a picture of the alcometer in the parrot showing the drop. Move it around and see what happens. Mech did you try it in the top or only the bottom?

If I had the money I would buy enough to fill my column and see what happens. I'm taking a piece into my old work and get someone there to work out the surface area and surface tension of this stuff.

I have a feeling these figures are going to come back at practically zero.

I weighed what was left of my 2lb roll. I have 290 grams left. My roll is tight, I have over 600 grams in it shoved into a 4inch column so it is definitely not a "not packed tight enough" problem. I am still absolutely positive it has to do with the very low surface tension and area of the copper mesh. I have 2 inches left at the top between the bottom of the condenser and the packing. My roll is about 5 inches wide, plus the 2 inches to the condenser. So if i am right and its the low area and surface tension then basically i have air for 7 or 8 inches at the top.

@Floridacracker I am thinking it wouldn't last very long. If you haven't seen it in the flesh, it is very fine. Its almost like thick hair. 0.1 x 0.3mm.

@Mickiboi my copper mesh rolls have been at the top of my various columns for the last 5 years. While the copper does degrade over time I don't see any evidence of the build-up in the stainless packed sections. I suspect it may be due to the flushing of the packed column post run.

I'll tell you what I'll do, since I have plenty of both forms of packing here I'll repeat your experiment. I'll run with the packing as normal and fully log the run. Then I'll replace the copper packed section with a stainless packed section to see what the difference is.

I won't get around to this until near the end of January but if I can manage it sooner I'll post up the results. Feel free anyone else out there to replicate the experiment before me.

BTW, in all my previous columns the copper came from Chor Boy copper scrubbers. I've only been using the Amphora fine mesh for roughly a year now in the 6" packed section, it's holding up remarkably well. I'll post some close up macro pics of the current state of the packing soon.

Cheers,

Mech.

This is Amphora mesh after 4-5 runs in a 3" VM. Before and after an acid/base/water soak.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

What are the flattens copper sleeves in there and what's there purpose @punkin

I believe they are used as a means of redirecting the the flow back to the center of the column so not to run to the side walls back the the boiler. This manner allows the return distill-it to acquire more abv as the vapor head`s up the column as it now has a greater surface area.

The day you quit learning is the day you start dying!

"I am an incurable gadgeteer, and I like enormously to set up a theory and then track down the consequences" Murray Leinster youtube.com/watch?v=08e9k-c91E8

Yes mate centerers.

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand