Welcome!

Be part of our community & join our international next generation forum now!

Categories

In this Discussion

- cleadus1 June 2013

- cooperville June 2013

- crozdog June 2013

- FullySilenced June 2013

- gr8brew June 2013

- harley June 2013

- Law_Of_Ohms November 2013

- Lloyd June 2013

- LunaBrille June 2013

- MOD2 June 2013

- Moonshine June 2013

- Myles June 2013

- Philter June 2013

- punkin June 2013

- RedDoorDistillery November 2013

- SDeurope June 2013

- Smaug June 2013

Comments

@MOD2, quite right done, it was a bit wrong there, sorry, and I had no opportunity myself to change this unfortunately ....

I apologize and hope that this will not happen again, but if it would make it again, so you will have to fix it again.

Cheers

@MOD2, I possible that you move my post that ended up wrong! To my new start page - link so I would be very grateful and can you can delete your and my last 2pc posts including this, so we all try to keep this side- link, page-commercial as clean as possible and with a content that strictly match the description of the page link ...

Cheers

Yes. This is a 350gallon 304SS dangerous goods IBC. I have added 8 1" element ports. And welded a 4" TC ferrule on the lid. I just got a new lid and I am adding a 8" TC ferrule to it for my new 8" Column. This is how it looks now as of today. I removed the IBC cooling water tote and hard plumbed it. The 275gal IBC of water was getting up to 180F just doing a strip run so it had to go.

harley. I use a digital system that I built for monitoring Temps. In the picture I do have a Dial Temp gauge right now in the column as I had a temp sensor fail and I need to replace it. But normally have have 4 points of temp being monitored on my display as seen here.

Thanks - great bit of "re-purposing" there. like the temp monitor too.

RDD, i relly like yours computer monitor it looks relly good.

As you should have realized that I am most well-read about them "hard pieces" and my personal opinion is that one should try to distill complete with 1pc distillation if you have the opportunity for this saves a lot of energy, but above all time ... now you have a low ceiling so wish or you can not increase it in any simple way, there are other options and Rednose has solved his problem with ceiling height of one in my eyes easily way, check out the link and you'll see a ss boiler with 2pc columns connected in series with about 13pc sieve plates together and produces 95% on 1pc distillation, now I know nothing of his strength on the mash ... but look at how easily he solved it by putting on 1pc distillation column next to the existing order in this way to gain access to several sieve plates so he get a stronger finished product in just 1pc distillation. Just a tip on one way to get axess to more plates ...

Destilerías e Alambiques

Cheers

ok, I want that temp monitor!, you said you made it yourself? a kit?

https://www.youtube.com/watch?v=ty6eY9VUIgI

Me too!

I just found this: VK011 Temperature Monitor Lite - looks like it...

here is the board: VK011: Serial Temperature Sensor Interface assembled or in kit form

It uses the DS1820 sensor several manufacturers provide free samples if you ask em :D eg DS18S20 1-Wire Parasite-Power Digital Thermometer

a lot of guys have developed Audrino solutions using them.

Nice find, Crozdog. Looks simple enough (for Law Of Ohms to build and send one to me :D )

Seems it needs an old-timey computer with a RS232 port? That might be hard to find.

Lots of cool toys to play with; charts, data logging and export to spreadsheet.

Maybe this discussion should be split off to keep this thread on track.

Really nice, and lot's of computers with RS232 avaiable, BUT freeware Windows only (not for Mac or Linux). :(

Your Place to be >>> www.StillDragon.org <<< Home of the StillDragon® Community Forum

Digitemp is a linux version logging as well

Yes that is it. I tired to use a RS232 to USB Cord but never could get it to work right. So I went back to using RS232. I have had an issue with sensors failing still troubleshooting why. They are rated to handle the Temps we run so that should not be an issue. I might be overheating them when I am soldering on the leads though.

Are you using good solder? I hate using that lead free stuff, and instead use one that contains silver. Solder one lead first, then allow some time to cool down before soldering the next two. Twist the wire around one lead of the sensor to hold it in place, apply the soldering iron to BOTH leads, then apply your solder. This soldering takes me about 1-2 seconds.

Sounds like a heatsink might come in handy

StillDragon Australia & New Zealand - Your StillDragon® Distributor for Australia & New Zealand

They make pci cards to put in your pc that have serial ports (rs232). Here are several options:

newegg search for "PCI RS232"

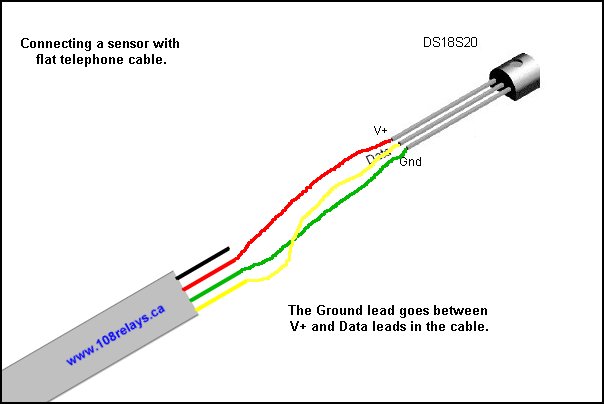

I always wait a bit between soldering each leg to let the heat dissipate. But I probably need to try using a heat-sink. I also read that I may need to keep the ground leg between the signal and the power leads in the cable jacket and then flip the ground to the outside at the sensor leg. This seams to help keep cross talk between the power and data line to a minimum.

are you using a 15watt soldering pencil to do this with? i got a ratshack one that's got two temp. ranges 15watt and 45watt... works a charm with rosin core

Are you able to use a different type of sensor lead, other than the telephone wire? Something like a stereo headset lead. Your local electronics shop should be able to offer you better wire for the sensors. This would reduce the noise and may give better results.

I don't seam to have any issues with the data being corrupted. But I have had 2 sensors that I built fail totally. Only after a few runs of use. The other 3 have been rock solid for many runs. No issues at all. So I think the phone line is working fine. I really think I just overheated the 2 that went bad when I was soldering on the leads so they failed shortly after being put into service.

I wouldn't use phone line to send the uV signals from the sensor, definatley agree with Philter on this one. I would be using sensor wire / sheilded mic cable.

https://www.youtube.com/watch?v=ty6eY9VUIgI

If using shielded cable remember to only ground 1 end!!!

Whenever I look at electric diagrams or read of electrical stuff ~X( my mind goes into overdrive

Not me coop. My eyes just glaze over and I mumble really dumb stuff for a few minutes and then I'm fine.

Well to me you guys are just showing off but i am very interested

There are many different sensor cables available but the standard system is to use a screened twisted pair for each sensor. However, the usual practice is to specify the sensor type, as you usually match the EMF/Temperature characteristics of the cable to the sensor type (K, J, T, N, R, S etc)

Well this is a good way to find out temp at the different measuring points, but the interesting thing for us commercial users is that you can control it automatically so you can copy the exact same results again and again ... when they've found their own optimal settings.

And they have different settings for different products and water-temperature in the reflux condenser would, for example, keep an accurate value constant throughout ( almost, to tail comes when you drive without reflux ) the process regardless of the temperature on the plate under reflux cooler without attending yourself and screw taps, etc. ...

This is one of the advantages of automatic reflux control system and Swede has a relatively simple and inexpensive system that fixes this for us commercial for smaller batches and hobby use, this is not so necessary ... It is the same with the effect on the boiler where it is a great advantage to be able to set it maximum and when you achieve a preselected temperature on the top plate to hold the control panel this temp and alerts, telling you that now is "we are there "and the distillation can be started ... With these "opportunities-features", you get the freedom that both have the ability to copy itself - their product, time and time again and also perform other duties in the meantime. For time is money for us commercial ....

So Please let os now leave the hobby level on this topic... Cheers

Very interesting little film clip from youtub on a micro distillery in Canada. Spontaneously, I can only say that this arrangement with wood burner, bottling in the same room, etc. would not be possible in the EU ... but something that I became interested in is the simple little band-manual machine that puts on the label when you roll on the bottle. Does anyone know were any solution to this simple label machin is sold, ore were a can by it ...

http://www.youtube.com/watch?v=viLoUidWxgw

Cheers

Easy Labeler - Affordable Manual Label Applicator Machines

These guys offer a few different machines for semi-manually applying labels off a roll.